Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

TOOLS & EQUIPMENT

MATERIALS & CONSUMABLES

VIDEO TUTORIAL

How to Cut Carbon Fibre Sheet, Tube and Parts

Introduction

Comprehensive video tutorial into the safety considerations and the best techniques and practices for shaping and cutting carbon fibre sheet, tube and parts (like a bike seatpost). We look at what safety gear is recommended and then what results you can expect from a range of different tools. Once we've cut the edges we also take a quick look at sealing cut edges.

In the video you'll find answers to the following commonly asked questions:

- Is Cutting Carbon Fibre Safe?

- Is Carbon Fibre Toxic or Dangerous?

- What respirator or dust mask do I need when cutting carbon fibre?

- What's the best way to cut down a carbon fiber seatpost or handlebars?

- How do I cut and shape carbon fibre sheet to make my own parts?

- How do professionals trim carbon fibre parts?

- Do I need to seal cut edges on a carbon fibre part?

- Can I cut carbon fibre with a hacksaw, Dremel, rodsaw, jigsaw, grinder etc.?

This How to Cut Carbon Fibre Sheet, Tube and Parts Video Tutorial will take you through the techniques and steps to assist you in getting the best results in your project.

TUTORIAL BREAKDOWN

1. Composition

Carbon Fibre is a composite material made up from cured resin and carbon fibre reinforcement. Both these materials have their own risks and considerations which will be covered in the following section.

2. Safety information

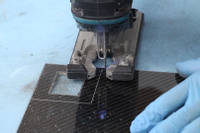

Our cutting advice section will demonstrate the use of a Hacksaw, Dremel Cutting Wheel, Junior Rodsaw, Angle Grinder and a Jigsaw using various blades on carbon fibre sheet and parts. You will also learn how to cut Carbon Fibre Tube and a Carbon Fibre Seat Post using a rotational cutting technique with power tools and hand tools.

3. Different cutting tools

Great finishes can be achieved on cut carbon fibre sheet, tube and parts by using sanding blocks, files, metal working tools and wet and dry abrasive paper - working through the grits to achieve the finish required.

4. Cutting carbon fibre tube

Our cutting advice section will demonstrate the use of a Hacksaw, Dremel Cutting Wheel, Junior Rodsaw, Angle Grinder and a Jigsaw using various blades on carbon fibre sheet and parts. You will also learn how to cut Carbon Fibre Tube and a Carbon Fibre Seat Post using a rotational cutting technique with power tools and hand tools.

5. Shaping and finishing

Great finishes can be achieved on cut carbon fibre sheet, tube and parts by using sanding blocks, files, metal working tools and wet and dry abrasive paper - working through the grits to achieve the finish required.

6. Sealing cut edges

In some circumstances it is beneficial to protect cut edges and this can be achieved easily by using epoxy resin and a lint free wipe to apply a thin coating of resin to the cut edge.

DISCUSSION (10)

Please share any questions or comments you may have about this video tutorial.

Hi Ronald, yes it is. Clearly the strength of a tube that's been 'slit' in this way will be compromised but in principle there's no problem with cutting down the length of a carbon tube. You'll also find that a carbon fibre tube that uses 100% down its length (like a pultruded tube for example) will feel particularly vulnerable to crushing or further splitting when cut in this way but that's really because they're already vulnerable.

LEAVE A COMMENT OR QUESTION

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

TOOLS & EQUIPMENT

MATERIALS & CONSUMABLES

DISCUSSION (10)

Please share any questions or comments you may have about this video tutorial.

Hi Ronald, yes it is. Clearly the strength of a tube that's been 'slit' in this way will be compromised but in principle there's no problem with cutting down the length of a carbon tube. You'll also find that a carbon fibre tube that uses 100% down its length (like a pultruded tube for example) will feel particularly vulnerable to crushing or further splitting when cut in this way but that's really because they're already vulnerable.

LEAVE A COMMENT OR QUESTION

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2024. All rights reserved.