Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Width | 600 | mm |

|---|---|---|

| Areal Weight | 100 | g/m² |

| Resin Weight | 50 | % |

| Consolidated Thickness | 0.15 | mm |

Fabric Specification

| Fibre Specifics | FlaxTape 110gsm | |

|---|---|---|

| Fibre Orientation | Unidirectional | |

| Weave | Unidirectional |

Product Data

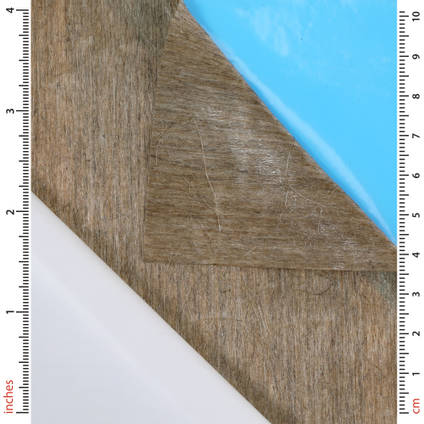

| Colour | Brown | |

|---|---|---|

| Type | Component Prepreg | |

| Format | Unidirectional | |

| Fibre Type | Flax Fibre | |

| Brand | FlaxPreg |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Min Cure Temp | 110 | °C |

| Max Cure Temp | 150 | °C |

| Glass Transition Temperature | 141 | °C |

General Properties

| Gross Weight | 0.9 | kg |

|---|---|---|

| Brand | Eco-Technilin |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

FLAXPREG 110g Unidirectional Prepreg Flax Fibre (600mm)

- Eco-Technilin

- FF-PP-UD-110-60-2

- No reviews

FLAXPREG-T-UD-110 is an uncured, epoxy matrix prepreg made using 100gsm unidirectional flax reinforcement. It can be laminated and cured in much the same was a carbon or glass prepreg, or cured alongside them.

Whilst an autoclave will produce the best results and surface finish, FLAXPREG can be used in an oven under vacuum-only conditions (out-of-autoclave).

The reinforcement is 600mm wide and available in rolls of 2, 10 and 90 linear metres.

PRODUCT VERSIONS

Roll Length

AVAILABILITY:4 in stock available for immediate shipping

45 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

This uncured prepreg is made using 110gsm unidirectional flax fibre with 50% RW epoxy matrix (resulting in an overall weight of 220gsm) and is laminated and cured in just the same was as a conventional glass or carbon fibre prepreg.

Like all ‘prepreg’ reinforcements supplied by Easy Composites, it is stored frozen (at -20°C) and shipped to customers straight from our freezers however the prepreg does have an outlife of 6-8 weeks at 23°C and so can travel safely on normal transport and does not necessarily need to be stored frozen on receipt.

For a UD reinforcement, FLAXPREG is surprisingly conformable and easy to laminate and is quite capable of conforming around tight and complex mould shapes and contours, as can be seen in the additional image of an S-Bend intake component, laminated using a FLAXPREG surface ply.

About Flax Fibre

Flax fibre is environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass fibre.

Although flax fibre offers lower overall strength and stiffness compared to reinforcements such as glass fibre, it does offer particular advantages in vibration damping and sound absorption, along with adequate mechanical properties and a natural aesthetic to complement its environmental credentials.

How to Process

FLAXPREG can be cured at temperatures from 110°C (2hrs, resulting in a >113°C Tg) to 150°C (30mins, resulting in a >136°C Tg).

Although the prepreg is primarily designed for curing under positive pressure, such as in an autoclave or hot-press, good results can be achieved under vacuum pressure-only oven cure (out-of-autoclave) where the main compromise is likely to be some slight dryness of the surface texture.

See datasheet for full details on storage, handling and cure cycles.

Typical Uses

This UD flax prepreg can be used on its own (in multiple plies) or combined with other prepreg reinforcements (provide they have similar cure profiles and rheology). When used in combination with other reinforcements, FLAXPREG can be used to provide a natural appearance or to add vibration damping properties to glass or carbon prepreg laminates.

FLAXPREG is already being successfully used in volume production for automotive interior trim components.

- Canoes, kayaks, and paddleboards

- Skis, snowboards, skateboards

- Dinghies, yachts

- Furniture, architectural mouldings, and panels

- Dashboards, car interior trim

How to Buy

This 110g unidirectional prepreg reinforcement is 600mm (~16") wide and is available in rolls of 2, 10 and 90 linear metres.

About Eco-Technilin

With 20 years of experience, France-based Eco-Technilin is the European leader in the technical use of natural fibres. Easy Composites are proud to be the exclusive UK distributor for Eco-Technilin and support them in their goal to make environmentally friendly technical materials as affordable and accessible as possible.

This uncured prepreg is made using 110gsm unidirectional flax fibre with 50% RW epoxy matrix (resulting in an overall weight of 220gsm) and is laminated and cured in just the same was as a conventional glass or carbon fibre prepreg.

Like all ‘prepreg’ reinforcements supplied by Easy Composites, it is stored frozen (at -20°C) and shipped to customers straight from our freezers however the prepreg does have an outlife of 6-8 weeks at 23°C and so can travel safely on normal transport and does not necessarily need to be stored frozen on receipt.

For a UD reinforcement, FLAXPREG is surprisingly conformable and easy to laminate and is quite capable of conforming around tight and complex mould shapes and contours, as can be seen in the additional image of an S-Bend intake component, laminated using a FLAXPREG surface ply.

About Flax Fibre

Flax fibre is environmentally friendly and sustainable alternative to traditional composite reinforcements such as glass fibre.

Although flax fibre offers lower overall strength and stiffness compared to reinforcements such as glass fibre, it does offer particular advantages in vibration damping and sound absorption, along with adequate mechanical properties and a natural aesthetic to complement its environmental credentials.

How to Process

FLAXPREG can be cured at temperatures from 110°C (2hrs, resulting in a >113°C Tg) to 150°C (30mins, resulting in a >136°C Tg).

Although the prepreg is primarily designed for curing under positive pressure, such as in an autoclave or hot-press, good results can be achieved under vacuum pressure-only oven cure (out-of-autoclave) where the main compromise is likely to be some slight dryness of the surface texture.

See datasheet for full details on storage, handling and cure cycles.

Typical Uses

This UD flax prepreg can be used on its own (in multiple plies) or combined with other prepreg reinforcements (provide they have similar cure profiles and rheology). When used in combination with other reinforcements, FLAXPREG can be used to provide a natural appearance or to add vibration damping properties to glass or carbon prepreg laminates.

FLAXPREG is already being successfully used in volume production for automotive interior trim components.

- Canoes, kayaks, and paddleboards

- Skis, snowboards, skateboards

- Dinghies, yachts

- Furniture, architectural mouldings, and panels

- Dashboards, car interior trim

How to Buy

This 110g unidirectional prepreg reinforcement is 600mm (~16") wide and is available in rolls of 2, 10 and 90 linear metres.

About Eco-Technilin

With 20 years of experience, France-based Eco-Technilin is the European leader in the technical use of natural fibres. Easy Composites are proud to be the exclusive UK distributor for Eco-Technilin and support them in their goal to make environmentally friendly technical materials as affordable and accessible as possible.

Specification

Weight and Dimensions

| Width | 600 | mm |

|---|---|---|

| Areal Weight | 100 | g/m² |

| Resin Weight | 50 | % |

| Consolidated Thickness | 0.15 | mm |

Fabric Specification

| Fibre Specifics | FlaxTape 110gsm | |

|---|---|---|

| Fibre Orientation | Unidirectional | |

| Weave | Unidirectional |

Product Data

| Colour | Brown | |

|---|---|---|

| Type | Component Prepreg | |

| Format | Unidirectional | |

| Fibre Type | Flax Fibre | |

| Brand | FlaxPreg |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Min Cure Temp | 110 | °C |

| Max Cure Temp | 150 | °C |

| Glass Transition Temperature | 141 | °C |

General Properties

| Gross Weight | 0.9 | kg |

|---|---|---|

| Brand | Eco-Technilin |

ASK YOUR OWN QUESTION

Customer Product Reviews for FLAXPREG 110g Unidirectional Prepreg Flax Fibre (600mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.