Need any help or advice?+44 (0)1782 454499

Specification

| Ends | 8 | cm |

|---|

Fabric Specification

| Picks | 8 | cm |

|---|---|---|

| Colour | White | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

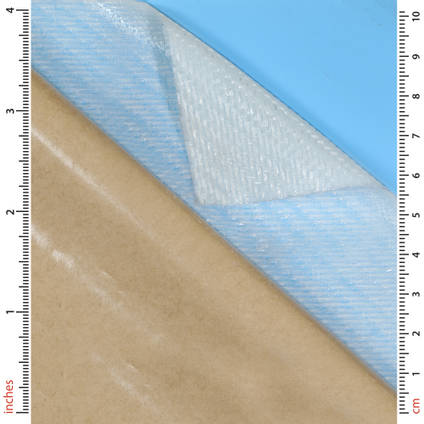

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Fibre Type | Glass Fibre |

Typical Laminate Properties

| Tg Onset (DMA) | 140 | °C |

|---|---|---|

| Tg Peak (DMA) | 148 | °C |

Fibre Properties

| UV Resistance | Good | |

|---|---|---|

| Freezer-life (at -18°C) | 12 | Months |

| Out-life (at 20°C) | 30 | Days |

| Width | 1270 | mm |

| Min Cure Temp | 80 | °C |

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Resin Weight | 38 | % |

| Consolidated Thickness | 0.3 | mm |

| Areal Weight | 280 | g/m² |

General Properties

| Gross Weight | 1.22 | kg |

|---|---|---|

| Brand | XPREG |

Shipping Information

Classification

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen.

This prepreg has a particularly short 'out-life' and for the best performance, the amount of time it spends at room temperature should be kept to an absolute minimum.

During summer months or periods of hot weather, only order this prepreg at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend. Alternatively, please contact us to discuss alternative shipping arrangements.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small additional handling charge will apply when shipping to some countries and regions. When applicable, this handling charge will be included in the automatic shipping calculation shown on the basket page.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

XC130 280g 2/2 Twill Prepreg Glass Fibre (1270mm)

- XPREG

- XC130-G41T2-280(1270)-1

- No reviews

Industry standard XPREG XC130 prepreg system with glass fibre reinforcement, designed for autoclave or hot-press cure. Oven and vacuum bag (OOA) cure is possible but will require some finishing work.

Glass fibre prepreg is an alternative to carbon fibre prepreg for less demanding applications, or those where carbon fibre is either not permitted, or problematic.

This prepreg reinforcement is 1.27m (1270mm) wide and available in 1m, 5m and 33m roll lengths.

PRODUCT VERSIONS

Roll Length

AVAILABILITY:2 in stock available for immediate shipping

0 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

XPREG® XC130 is an epoxy-based component autoclave prepreg system with a 130°C maximum service temperature developed for autoclave or other positive pressure cure. The prepreg listed on this page uses a 280g 2x2 twill Hexcel glass fibre reinforcement and is 1270mm wide.

This toughened resin system offers convenient processing and excellent mechanical properties. XC130 has a long out-life (at least 30 days at 20°C) with an intermediate tack level making for easy handling and laminating whilst its variable cure temperature from 80°C allows a wide range of mould systems to be used.

Typical Uses

XC130 is the recommended system for the manufacture of both structural and cosmetic applications where components will be cured in an autoclave or otherwise under positive pressure (such as heated platen press).

This 280g 2x2 twill glass fibre reinforced prepreg is as an alternative to our carbon fibre reinforced prepregs and can be used in less structurally demanding applications or those where carbon fibre reinforcement is either not permitted, such as vintage racing, or where carbon fibre is problematic, such as components requiring radio transparency.

- High-end GRP components

- UAV fuselages, radio canopies

- Vintage car/bike components

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the drop-down list at the top of the page. When ordering a full roll of fabric the drop-down list shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of pre-preg.

Further Information

Curing

Autoclave Cure

XPREG® XC130 is designed to be autoclave cured or otherwise cured under positive pressure (such as heated platen or pressurised bladder).

Initial cure is possible from 80°C although service temperature will be determined by the final cure temperature.

Out-of-Autoclave Cure

Unlike with our carbon fibre prepregs, Easy Composites does not supply an XC110 (out-of-autoclave cure) glass reinforced prepreg. The reason for this is because the XC110 system does not reliably produce the trademark ‘pin-hole free’ surface finish when curing glass reinforced laminates under vacuum pressure and oven cure only.

In situations where you want to use a glass prepreg and cure out-of-autoclave, this XC130 glass prepreg can be used, although minor surface pin-holes, requiring some finishing, should be expected.

CURE CYCLES AND RESULTING Tg

| Cure Temp | Comments | Initial Min Cure Time | Resulting Tg |

|---|---|---|---|

| 80°C | (Minimum) | 16hrs | 90°C |

| 90°C | 8hrs | 100°C | |

| 100°C | 4hrs | 110°C | |

| 120°C | (Maximum) | 2hrs | 120°C |

| 130°C | Post Cure | 2hrs | 140°C |

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

Fully Compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

It is not recommended to use hand laminated Uni-Mould tools in an autoclave due to the likelihood that voids within the moulds will cause blisters and distortion in the mould at elevated temperature and pressure.

Storage and Handling

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging.

Remaining material should be re-sealed before returning to the freezer to avoid the risk of moisture uptake.

XPREG® XC130 is an epoxy-based component autoclave prepreg system with a 130°C maximum service temperature developed for autoclave or other positive pressure cure. The prepreg listed on this page uses a 280g 2x2 twill Hexcel glass fibre reinforcement and is 1270mm wide.

This toughened resin system offers convenient processing and excellent mechanical properties. XC130 has a long out-life (at least 30 days at 20°C) with an intermediate tack level making for easy handling and laminating whilst its variable cure temperature from 80°C allows a wide range of mould systems to be used.

Typical Uses

XC130 is the recommended system for the manufacture of both structural and cosmetic applications where components will be cured in an autoclave or otherwise under positive pressure (such as heated platen press).

This 280g 2x2 twill glass fibre reinforced prepreg is as an alternative to our carbon fibre reinforced prepregs and can be used in less structurally demanding applications or those where carbon fibre reinforcement is either not permitted, such as vintage racing, or where carbon fibre is problematic, such as components requiring radio transparency.

- High-end GRP components

- UAV fuselages, radio canopies

- Vintage car/bike components

How to Buy

All XPREG® prepregs are stored on site in our freezers. To reduce handling time and allow same-day dispatch, prepregs are available in pre-cut roll lengths. Choose the roll length you require from the drop-down list at the top of the page. When ordering a full roll of fabric the drop-down list shows the typical roll length but please allow for length variance of plus or minus 1m which has already been factored into the low unit price of our full length rolls.

Your XPREG® prepreg is sealed in air-tight packaging and will ship from us still frozen. Please see the transport tab for further details and important information about delivery.

The Sample Pack Contains two 400x300mm (15.7x11.8") pieces of pre-preg.

Further Information

Curing

Autoclave Cure

XPREG® XC130 is designed to be autoclave cured or otherwise cured under positive pressure (such as heated platen or pressurised bladder).

Initial cure is possible from 80°C although service temperature will be determined by the final cure temperature.

Out-of-Autoclave Cure

Unlike with our carbon fibre prepregs, Easy Composites does not supply an XC110 (out-of-autoclave cure) glass reinforced prepreg. The reason for this is because the XC110 system does not reliably produce the trademark ‘pin-hole free’ surface finish when curing glass reinforced laminates under vacuum pressure and oven cure only.

In situations where you want to use a glass prepreg and cure out-of-autoclave, this XC130 glass prepreg can be used, although minor surface pin-holes, requiring some finishing, should be expected.

CURE CYCLES AND RESULTING Tg

| Cure Temp | Comments | Initial Min Cure Time | Resulting Tg |

|---|---|---|---|

| 80°C | (Minimum) | 16hrs | 90°C |

| 90°C | 8hrs | 100°C | |

| 100°C | 4hrs | 110°C | |

| 120°C | (Maximum) | 2hrs | 120°C |

| 130°C | Post Cure | 2hrs | 140°C |

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

Fully Compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

It is not recommended to use hand laminated Uni-Mould tools in an autoclave due to the likelihood that voids within the moulds will cause blisters and distortion in the mould at elevated temperature and pressure.

Storage and Handling

When not in use, XPREG® prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging.

Remaining material should be re-sealed before returning to the freezer to avoid the risk of moisture uptake.

Specification

| Ends | 8 | cm |

|---|

Fabric Specification

| Picks | 8 | cm |

|---|---|---|

| Colour | White | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Fibre Type | Glass Fibre |

Typical Laminate Properties

| Tg Onset (DMA) | 140 | °C |

|---|---|---|

| Tg Peak (DMA) | 148 | °C |

Fibre Properties

| UV Resistance | Good | |

|---|---|---|

| Freezer-life (at -18°C) | 12 | Months |

| Out-life (at 20°C) | 30 | Days |

| Width | 1270 | mm |

| Min Cure Temp | 80 | °C |

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Resin Weight | 38 | % |

| Consolidated Thickness | 0.3 | mm |

| Areal Weight | 280 | g/m² |

General Properties

| Gross Weight | 1.22 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

ASK YOUR OWN QUESTION

Customer Product Reviews for XC130 280g 2/2 Twill Prepreg Glass Fibre (1270mm)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Classification

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen.

This prepreg has a particularly short 'out-life' and for the best performance, the amount of time it spends at room temperature should be kept to an absolute minimum.

During summer months or periods of hot weather, only order this prepreg at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend. Alternatively, please contact us to discuss alternative shipping arrangements.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small additional handling charge will apply when shipping to some countries and regions. When applicable, this handling charge will be included in the automatic shipping calculation shown on the basket page.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.