Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

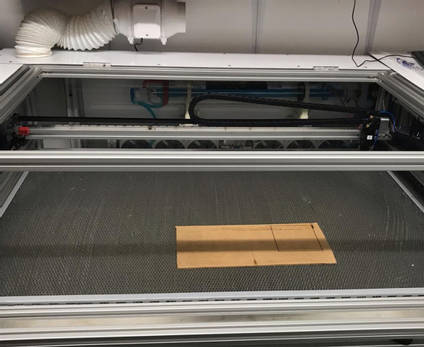

Aluminium Honeycomb Bed for DIY Laser Cutting Machine

Scott decided to build his own CO2 laser cutting machine from scratch. After drawing the design in CAD, he was ready to start the build. The main frame was based on aluminium profiles which were linked together.

A large selection of parts needed to be designed then 3D printed. A Raspberry PI is used for controlling the lights, fans, water pump and various safety features. An Arduino was used and programmed to interpret the G code into the movement of the laser head. The various parts were assembled to create the prototype laser cutter.

A key part of the set up is the need for a honeycomb cutting bed. This is a sacrificial element which allows support of the workpiece, keeping it flat, and also allowing the waste material and heat to escape into the bed. It also reduces some of the laser reflection back at the material being cut.

The honeycomb selected was the 6.4mm cell size in a 20mm thickness. Once expanded, the honeycomb was mounted into a frame made from steel channel to support it. The frame was then mounted as a bed to the laser cutter. Now completed, the laser cutter has been used to cut various materials for several new projects.

ABOUT SCOTT FREEMAN

Scott wanted to build a laser cutter to cut the various materials he uses in some of his projects. He decided to document the project on his Design Lab YouTube channel.

CONTACT INFORMATION

| YouTube | www.youtube.com/designlab2020 |

|---|

| @designlab2020 |

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

ABOUT SCOTT FREEMAN

Scott wanted to build a laser cutter to cut the various materials he uses in some of his projects. He decided to document the project on his Design Lab YouTube channel.

CONTACT INFORMATION

| YouTube | www.youtube.com/designlab2020 |

|---|

| @designlab2020 |

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.