Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

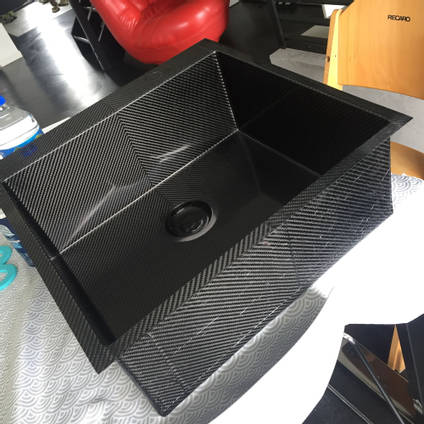

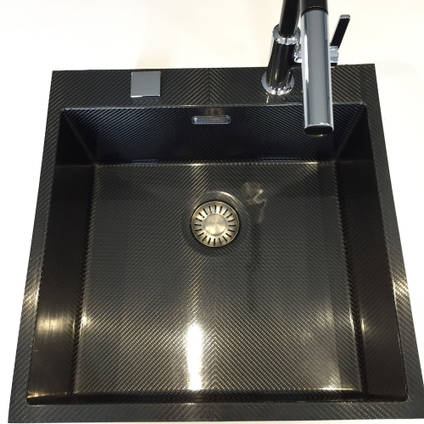

Carbon Fibre Sink

These fantastic carbon fibre sinks were created using our XC110 Out of Autoclave Pre-preg carbon fibre. Firstly a pattern for each of the sink designs was created to the exact shape wanted for each design. Then the EG160 High Temperature Tooling Gelcoat and EL160 High Temperature Resin was used to create the moulds. The moulds were very highly finished and polished so that a good result was achieved straight from the mould.

The carbon itself was then laid up. Extra care was taken to ensure perfect alignment of each piece of fabric corresponding to each flat surface on the sink. This even included a V-weave style pattern in the centre with all the fabric around it aligned to ensure the pattern was consistent across the part. The lay up consisted of one layer of our XC110 210g and 2 layers of the XC110 416g cloth which gave a laminate just over 1.25mm thick.

The sink was then vacuum bagged and cured in an oven. Once cured, the stunning looking sink was demoulded then finished off by trimming to shape and fitting all the plumbing parts to suit the desired look.

You can find a few more examples of Aymerics work in the gallery including a V-weave carbon fibre sink- be sure to check it out!

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.