Need any help or advice?+44 (0)1782 454499

Specification

Weight and Dimensions

| Length | 250 | mm |

|---|---|---|

| Width | 230 | mm |

| Thickness | 0.35 | mm |

| Thickness Tolerance (+/-) | 0.1mm | mm |

Product Data

| Colour | Black | |

|---|---|---|

| Appearance | 2x2 Twill (Glossy) | |

| Type | Single Sided | |

| Resin Matrix | Epoxy |

Fabric Specification

| Fibre Orientation | 0, 90 |

|---|

Mechanical Properties

| Tg Onset (DMA) | 80 | °C |

|---|

General Properties

| Gross Weight | 0.4 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Carbon Fibre Veneer Sheet

- CFS-RI-SA-025-0056

- 5/5 Average rating

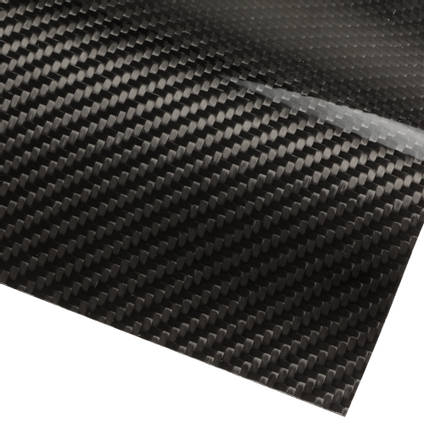

Manufactured by Easy Composites in the UK. Super-thin flexible carbon fibre veneer with a high gloss finish on one side. This thin layer of genuine carbon fibre sheet is easily cut and shaped and can be bonded to existing surfaces such as shop-fittings, architectural features, exhibition displays, dashboards, desks and more.

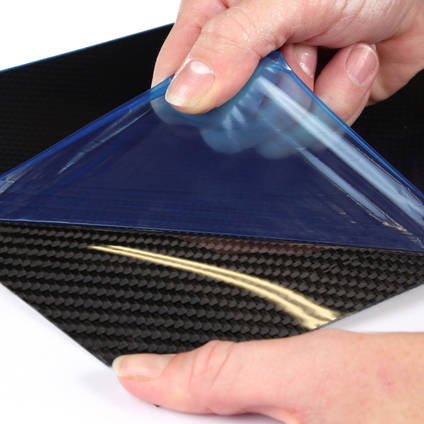

Available with or without a 3M self-adhesive backing in range of sizes up to 2sqm.

PRODUCT VERSIONS

Sheet Size

Version

AVAILABILITY:6 in stock available for immediate shipping

Trade discounts

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| £11.00 | £10.50 | £10.00 | £8.75 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

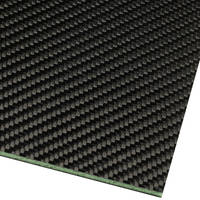

Extra thin genuine carbon fibre veneer suitable for a range of applications where the appearance of genuine carbon fibre is required in a format that can be bonded to the surface of other materials to create an attractive, high gloss veneer surface.

The sheet is designed to sit very flat having minimal variation in thickness and is available with a peel-ply finish to the reverse - perfect for bonding to other materials tion.

The 'A-side' of the sheet has the classic 2/2 twill, 3k woven carbon fibre appearance with a pin-hole free high gloss finish. The reverse of the sheet features an even textured 'peel ply' finish.

Typical Uses

This flexible carbon fibre sheet is ideal for use in furniture making, architectural detailing or adding genuine carbon fibre appearance to just about any flat surface.

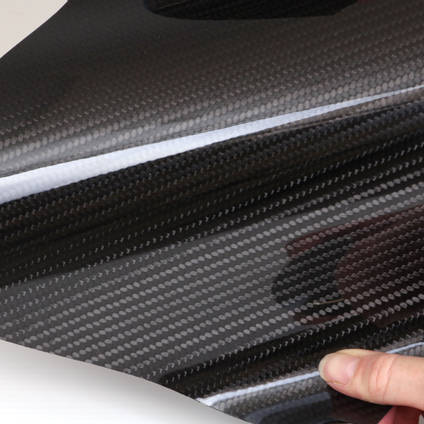

At approximately 0.25mm, the veneer can easily follow single plane curves (like the radiused edge of a desk for example) but, in common with most carbon surfaces, it will eventually break if bent too far.

How to Buy

Sheet sizes range from 250 x 225mm up to large format 2000mm x 980mm. Please note that dimensions are nominal and sheets will often be supplied oversized.

Choose the sheet size you require using the drop down list at the top of the page.

Further Information

Cutting, Shaping & Finishing

As with all carbon fibre and composites (like fibreglass, carbon kevlar etc) good results can be achieved for cutting, shaping and finishing this sheet using regular workshop tools like hacksaws, jigsaws and wet-and-dry. In fact, this ultra thin veneer can actually be cut using strong scissors. Specialist tools can, however, make lighter work of the job and produce better results.

Laminate Composition

This carbon fibre sticker sheet is resin infused from a single layer of top quality 2/2 Twill 210gsm carbon fibre. This is the same fabric used in our other infused sheet. Further details along with the fabric specification and fibre type, can be seen on the Specification tab.

The matrix used is a high performance epoxy resin which offers excellent mechanicals, clarity and improved UV stability. The high temperature cure maximises the mechanical strength properties and results in a Tg (glass transition) of 80°C.

Trade discounts

| 0-4 | 5-9 | 10-19 | 20+ |

|---|---|---|---|

| £11.00 | £10.50 | £10.00 | £8.75 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Extra thin genuine carbon fibre veneer suitable for a range of applications where the appearance of genuine carbon fibre is required in a format that can be bonded to the surface of other materials to create an attractive, high gloss veneer surface.

The sheet is designed to sit very flat having minimal variation in thickness and is available with a peel-ply finish to the reverse - perfect for bonding to other materials tion.

The 'A-side' of the sheet has the classic 2/2 twill, 3k woven carbon fibre appearance with a pin-hole free high gloss finish. The reverse of the sheet features an even textured 'peel ply' finish.

Typical Uses

This flexible carbon fibre sheet is ideal for use in furniture making, architectural detailing or adding genuine carbon fibre appearance to just about any flat surface.

At approximately 0.25mm, the veneer can easily follow single plane curves (like the radiused edge of a desk for example) but, in common with most carbon surfaces, it will eventually break if bent too far.

How to Buy

Sheet sizes range from 250 x 225mm up to large format 2000mm x 980mm. Please note that dimensions are nominal and sheets will often be supplied oversized.

Choose the sheet size you require using the drop down list at the top of the page.

Further Information

Cutting, Shaping & Finishing

As with all carbon fibre and composites (like fibreglass, carbon kevlar etc) good results can be achieved for cutting, shaping and finishing this sheet using regular workshop tools like hacksaws, jigsaws and wet-and-dry. In fact, this ultra thin veneer can actually be cut using strong scissors. Specialist tools can, however, make lighter work of the job and produce better results.

Laminate Composition

This carbon fibre sticker sheet is resin infused from a single layer of top quality 2/2 Twill 210gsm carbon fibre. This is the same fabric used in our other infused sheet. Further details along with the fabric specification and fibre type, can be seen on the Specification tab.

The matrix used is a high performance epoxy resin which offers excellent mechanicals, clarity and improved UV stability. The high temperature cure maximises the mechanical strength properties and results in a Tg (glass transition) of 80°C.

Specification

Weight and Dimensions

| Length | 250 | mm |

|---|---|---|

| Width | 230 | mm |

| Thickness | 0.35 | mm |

| Thickness Tolerance (+/-) | 0.1mm | mm |

Product Data

| Colour | Black | |

|---|---|---|

| Appearance | 2x2 Twill (Glossy) | |

| Type | Single Sided | |

| Resin Matrix | Epoxy |

Fabric Specification

| Fibre Orientation | 0, 90 |

|---|

Mechanical Properties

| Tg Onset (DMA) | 80 | °C |

|---|

General Properties

| Gross Weight | 0.4 | kg |

|---|

This carbon veneer, although very flexible for a rigid cured composite, can only be bent around curves in one direction and thus would not be suitable to skin a complex curved part. However, we do offer kits for carbon skinning where using the raw fabric and resins, you can skin over complex shapes. You can see our range of skinning kits here: XCR Carbon Fibre Skinning Starter Kit. You will also find at the link a tutorial video that takes you through the process from start to finish.

Yes the veneer sheet is ideal for such applications. It is easy to cut and if you go for the Self Adhesive Version, just as easy to fit with the strong adhesive on it. Just ensure the surface has been thoroughly cleaned and degreased to help the adhesive get a good bond.

Whether or not cut edges would benefit from sealing really comes down to the application and environment where the sheet will be used, specifically, we're really talking about prolonged or permanent exposure to liquids like water, chemicals, oil etc. In an application where the cut edge of the sheet is going to be regularly or permanently exposed to liquids then it would be beneficial to seal the edge to prevent water ingress which, over enough time, can travel down the fibres and cause delamination.

Based on the above, if edge sealing is deemed advantageous then it's best done using some epoxy resin which should be mixed (according to its accompanying instructions) and either be brushed or smeared on the cut edge, or the cut edge dipped in it. Although it's by no means critical, a particularly suitable resin would be our XCR Epoxy Coating Resin.

Good question! The 0.25mm sheet is thin enough to be cut with scissors/shears but they do need to be sharp and provide a reasonable amount of leverage and providing this is the case, you wouldn't expect to see any noticeable cracking or chipping. Alternatives to scissors or shears would be a hacksaw (a metal blade with fine teeth or a gritted blade, like one you'd use for tile cutting would work well) or you can use things like a rotary cutting disk in a tool like a Dremel, but all of these are probably overkill for the 0.25mm sheet. In all cases, the edge can be smoothed and refined very quickly and easily using a bit of abrasive paper.

Compared to a properly bonded surface, the 3M adhesive would not be as strong. Most structural adhesives are stronger than the carbon itself, which for cosmetic applications is stronger than necessary. Hence the 3M adhesive offers an easy and convenient method of application for most cosmetic uses.

The sheet has a high level of UV resistance, but in common with all epoxy based composites, is not fully UV stable. It depends on the environment and UV exposure but eventually the sheet will show yellowing. You can spray it with a UV stable lacquer to get more protection should you wish.

The radius depends how it is being loaded, however, in practice, a radius less than around 30mm is likely to lead to the carbon fibre cracking and failing.

The 3M backing has a thickness of 0.13mm.

The sheet cannot be bent with heat. The epoxy resin is a thermoset resin so is unable to be softened with heat.

ASK YOUR OWN QUESTION

Customer Product Reviews for Carbon Fibre Veneer Sheet

Been using these adhesive sheets for nearly 4 years and I must say it’s fantastic. However in the beginning I did have a few sheets with pin hole imperfections in the resin finish and the film hard to remove leave residue. The film seems to be way easier to remove and quality or carbon has been fantastic. Brilliant company and service

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.