Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

CUSTOMER GALLERY

Custom Carbon Fibre iPhone Cover

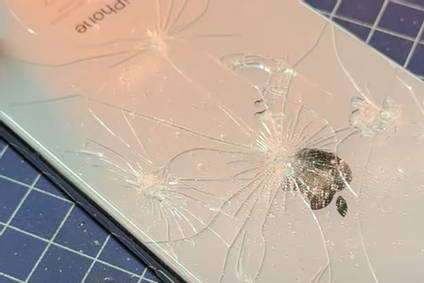

The latest project from PeteeLab is a custom carbon fibre cover for an iPhone.

The first step was to remove the broken display and back glass, followed by replacing the plastic edge with a carbon fibre upgrade.

After measuring the necessary dimensions, the mould was designed and 3D-printed using PETG material. The mould surface was then prepared to ensure an easy demould.

The appropriate ratio of chopped tow and epoxy resin was then measured and the carbon fibre was layered in the mould for optimal strength and durability and left to cure.

Once cured, the cover was demoulded and the logo placement adjusted. The logo was then secured with epoxy, and the original frame polished to ensure a cohesive appearance.

Finally, the carbon fibre cover was adhered to the phone, resulting in a sleek, durable device that should withstand future drops!

A video of the process can be found here:Custom Carbon Fibre iPhone Case.

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.