Need any help or advice?+44 (0)1782 454499

Specification

Product Data

| Wall Thickness | 0.75 | mm |

|---|---|---|

| Colour | Clear | |

| Chemistry / Material | Polyethylene |

Weight and Dimensions

| Outside Diameter (OD) | 4.5 | mm |

|---|---|---|

| Inside Diameter (ID) | 3 | mm |

Mechanical Properties

| Max Service Temp | 60 | °C |

|---|

General Properties

| Gross Weight | 0.078 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Resin Infusion Spiral Standard Flow 10m Coil

- RISP-M-10

- No reviews

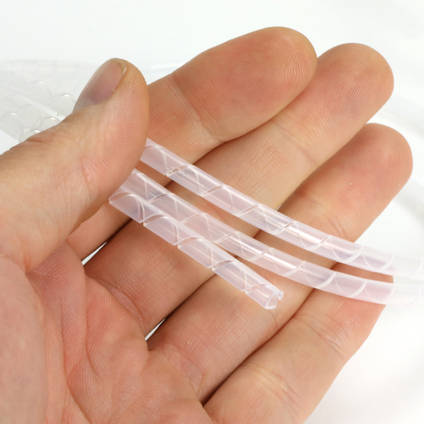

Standard flow plastic infusion spiral used to distribute resin flow in vacuum resin infusion of composite parts. 4.5mm OD (3mm ID) designed to be a perfect fit in the base of our resin infusion connectors.

Sold as a 10m pack. Volume discounts apply.

AVAILABILITY:More than 50 availablefor immediate shipping

Trade discounts

| 0-4 | 5-19 | 20+ |

|---|---|---|

| £3.50 | £3.00 | £2.00 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Infusion spiral is a spiral wound plastic tube which allows very easy flow or resin from the resin feed tube into and around a resin infusion project. Infusion spiral is typically positioned underneath the feed line directing resin flow into the further corners of the part.

This standard flow spiral has a 3mm ID (4.5mm OD) and is suitable for small to medium sized infusion projects (up to the size of a vehicle bonnet/hood) or for use on large projects where a slower resin distribution is required. The infusion spiral is made from polypropylene plastic and not suitable for high temperature use.

Like most other elements of the resin infusion process infusion mesh cannot be reused once resin has flown through it and therefore should be considered a disposable consumable of the process.

This resin infusion spiral is designed to fit perfectly into the base of our Resin Infusion Connector.

The price shown is per 10m pack of spiral. Volume discounts apply.

Trade discounts

| 0-4 | 5-19 | 20+ |

|---|---|---|

| £3.50 | £3.00 | £2.00 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Infusion spiral is a spiral wound plastic tube which allows very easy flow or resin from the resin feed tube into and around a resin infusion project. Infusion spiral is typically positioned underneath the feed line directing resin flow into the further corners of the part.

This standard flow spiral has a 3mm ID (4.5mm OD) and is suitable for small to medium sized infusion projects (up to the size of a vehicle bonnet/hood) or for use on large projects where a slower resin distribution is required. The infusion spiral is made from polypropylene plastic and not suitable for high temperature use.

Like most other elements of the resin infusion process infusion mesh cannot be reused once resin has flown through it and therefore should be considered a disposable consumable of the process.

This resin infusion spiral is designed to fit perfectly into the base of our Resin Infusion Connector.

The price shown is per 10m pack of spiral. Volume discounts apply.

Specification

Product Data

| Wall Thickness | 0.75 | mm |

|---|---|---|

| Colour | Clear | |

| Chemistry / Material | Polyethylene |

Weight and Dimensions

| Outside Diameter (OD) | 4.5 | mm |

|---|---|---|

| Inside Diameter (ID) | 3 | mm |

Mechanical Properties

| Max Service Temp | 60 | °C |

|---|

General Properties

| Gross Weight | 0.078 | kg |

|---|

The OD is 4.5mm.

The highest working temperature for the spiral is 60°C.

The spiral is not designed to be used at high temperature and really there are not many occasions when an infusion spiral would need to be able to take a high temperature. If you wanted to be able to postcure an infusion (after the infusion had comepleted) then it would not be a problem to postcure 'in mould' with the spiral still in place at a high temperature. All that would happen is that the spiral would soften considerably but if the infusion has already completed then this would not affect the laminate. If you need the spiral to maintain its shape and airflow at these temperatures then it should NOT be used for this purpose. instead you might need something like a silicone 'omega' section instead.

ASK YOUR OWN QUESTION

Customer Product Reviews for Resin Infusion Spiral Standard Flow 10m Coil

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

CUSTOMERS ALSO PURCHASED

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.