Need any help or advice?+44 (0)1782 454499

MB6/8 Split-Mould Clamping Bush

- MB6-12

- No reviews

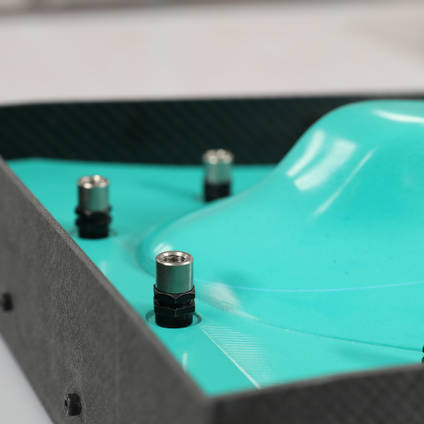

Hardened steel bushes designed specifically to be laminated in to prepreg composite split-moulds to provide accurate and durable clamping points when fastening/bolting split-moulds together.

Available in MB6 (M6) and MB8 (M8) versions. Sold individually.

PRODUCT VERSIONS

Size

AVAILABILITY:More than 200 availablefor immediate shipping

Trade discounts

| 0-9 | 10-49 | 50-99 | 100+ |

|---|---|---|---|

| £1.55 | £1.40 | £1.30 | £1.25 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

MB6 and MB8 are a custom-made evolution of the regular drill bushes that are often laminated into prepreg composite moulds to serve as fixing points when bolting split-moulds together.

Like regular drill bushes, MB6/8 are made of case-hardened steel but instead of a smooth outer profile they have two hexagon flanges to transfer the clamping load to the surrounding laminate and prevent rotation when using torque to remove the alignment pin or screws that have inadvertently become bonded to the bush after a cure cycle.

The bushes are designed to sit directly on the surface of the tool, rather than beneath one or two plies of laminate, which eliminates the burring of the laminate that can otherwise occur around the aperture after repeated use.

Further Information

How to Use

MB6/8 bushes are designed to be positioned on the pattern using extractable alignment pins (sold separately) which should be treated with release agent before use.

Positioning & Laminating

- Patterns are designed with holes machined into the pattern where the bushes will be located.

- Mould bushes are slid onto the alignment pins (with the hexagonal flanges at the top) which are then pushed into the positioning holes in the pattern.

- Typically, a donut-shaped ring of lighter tooling prepreg is used to surround the mould bush on the tool surface and then a 45 strip of the surface prepreg is wrapped around the mould bush before the rest of the surface ply is laminated. A debulk is often undertaken at this point.

- Heavier backing plies of tooling prepreg are then laminated around the mould bush and slightly up onto the sides of the alignment pin head.

- The mould is then cured according to the processing requirements of the tooling prepreg.

Extracting the Alignment Pins

Alignment pins should be extracted before the mould is separated from the pattern.

The pins have an M8 thread in their cap and can be extracted by T-handle, slide hammer or cordless drill:

- T-Handle Hex Driver: Lock an allen cap M8 screw to the pin using an M8 nut and twist the pin free using a T-handle hex driver.

- Slide Hammer: Attach a slide hammer to the pin using an M8 thread (a thread adapter might be required).

- Cordless Drill: The chuck of a cordless drill can be tightened over the head of the alignment pin to provide a steady rotation and lifting action though it may be preferable to ‘crack’ the bond first with a slide hammer or T-handle.

Once the alignment pins have been extracted, the mould can be separated from the pattern and the laminate around the pins ground flat before the mould is post-cured ready for use.

Mould sections are bolted together using 30mm M6/M8 allen cap screws and dome head nuts (sold separately).

Dimensions

| Overall Height | Flange Ø (max) | Internal Ø | Shank Ø | |

| MB6 | 12mm | 15mm | 6.1mm | 12mm |

| MB8 | 12mm | 15mm | 8.1mm | 12mm |

How to Buy

Our Split-Mould Clamping Bushes are sold individually but almost always used in pairs. They are available in MB6 (M6/6mm) and MB8 (M8/8mm) versions; in most cases we would recommend MB6 bushes for M6 fasteners which can provide more than enough clamping force for most moulds.

Volume discounts are available and apply automatically.

For positioning, MB6/MB8 bushes require an alignment pin (not included) which is extractable and reusable.

MB6/MB8 mould bushes are also available to buy as a complete set of two bushes together with an alignment pin, 30mm cap head screw and dome nut.

Trade discounts

| 0-9 | 10-49 | 50-99 | 100+ |

|---|---|---|---|

| £1.55 | £1.40 | £1.30 | £1.25 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

MB6 and MB8 are a custom-made evolution of the regular drill bushes that are often laminated into prepreg composite moulds to serve as fixing points when bolting split-moulds together.

Like regular drill bushes, MB6/8 are made of case-hardened steel but instead of a smooth outer profile they have two hexagon flanges to transfer the clamping load to the surrounding laminate and prevent rotation when using torque to remove the alignment pin or screws that have inadvertently become bonded to the bush after a cure cycle.

The bushes are designed to sit directly on the surface of the tool, rather than beneath one or two plies of laminate, which eliminates the burring of the laminate that can otherwise occur around the aperture after repeated use.

Further Information

How to Use

MB6/8 bushes are designed to be positioned on the pattern using extractable alignment pins (sold separately) which should be treated with release agent before use.

Positioning & Laminating

- Patterns are designed with holes machined into the pattern where the bushes will be located.

- Mould bushes are slid onto the alignment pins (with the hexagonal flanges at the top) which are then pushed into the positioning holes in the pattern.

- Typically, a donut-shaped ring of lighter tooling prepreg is used to surround the mould bush on the tool surface and then a 45 strip of the surface prepreg is wrapped around the mould bush before the rest of the surface ply is laminated. A debulk is often undertaken at this point.

- Heavier backing plies of tooling prepreg are then laminated around the mould bush and slightly up onto the sides of the alignment pin head.

- The mould is then cured according to the processing requirements of the tooling prepreg.

Extracting the Alignment Pins

Alignment pins should be extracted before the mould is separated from the pattern.

The pins have an M8 thread in their cap and can be extracted by T-handle, slide hammer or cordless drill:

- T-Handle Hex Driver: Lock an allen cap M8 screw to the pin using an M8 nut and twist the pin free using a T-handle hex driver.

- Slide Hammer: Attach a slide hammer to the pin using an M8 thread (a thread adapter might be required).

- Cordless Drill: The chuck of a cordless drill can be tightened over the head of the alignment pin to provide a steady rotation and lifting action though it may be preferable to ‘crack’ the bond first with a slide hammer or T-handle.

Once the alignment pins have been extracted, the mould can be separated from the pattern and the laminate around the pins ground flat before the mould is post-cured ready for use.

Mould sections are bolted together using 30mm M6/M8 allen cap screws and dome head nuts (sold separately).

Dimensions

| Overall Height | Flange Ø (max) | Internal Ø | Shank Ø | |

| MB6 | 12mm | 15mm | 6.1mm | 12mm |

| MB8 | 12mm | 15mm | 8.1mm | 12mm |

How to Buy

Our Split-Mould Clamping Bushes are sold individually but almost always used in pairs. They are available in MB6 (M6/6mm) and MB8 (M8/8mm) versions; in most cases we would recommend MB6 bushes for M6 fasteners which can provide more than enough clamping force for most moulds.

Volume discounts are available and apply automatically.

For positioning, MB6/MB8 bushes require an alignment pin (not included) which is extractable and reusable.

MB6/MB8 mould bushes are also available to buy as a complete set of two bushes together with an alignment pin, 30mm cap head screw and dome nut.

Specification

General Properties

| Gross Weight | 0.009 | kg |

|---|

ASK YOUR OWN QUESTION

Customer Product Reviews for MB6/8 Split-Mould Clamping Bush

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.RELATED PRODUCTS

RELATED PRODUCTS

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.