Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

Toyota Supra Complex Wing

Stefans biggest project so far was a complex wing for a Toyota Supra.

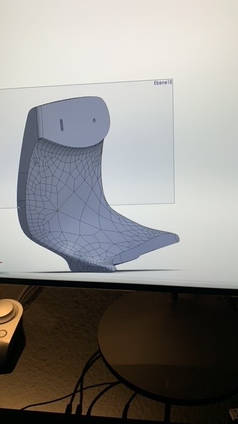

This also involved more advanced design techniques and included 3D scanning of parts and also re-working in CAD prior to 3D printing some of the parts. The complexity of the shapes for the stands meant each stand was a 3 piece mould.

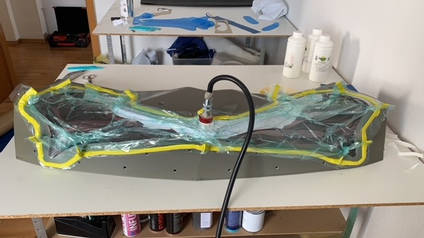

The wing blade itself was created from XPREG XC110 as a single piece part using a 2 part mould. The availability of tubular bagging film meant it could be cured as a single hollow piece. The finished wing and end supports were finished then bigHead Fasteners were used to enable the assembly of the final wing prior to fitting to the car.

Take a look at some of Stefan's other projects in the gallery.

ABOUT STRAIGHT FORWARD RACING TECHNOLOGIES

Stefan first got into working with composites by wrapping some interior car parts in carbon fibre, He then discovered Easy Composites video tutorials and embarked on his first prepreg project.

The first project was a little air scoop for an Audi TTRS intake system. He followed this project up by making an entire air box system for the same car, then another inlet pipe and the last big project was a wing for the new Toyota Supra.

You can see more of Stefan's projects in the gallery.

CONTACT INFORMATION

| www.facebook.com/straightforward |

| @straight_forwrd_rt |

| www.facebook.com/straightforward |

| @straight_forwrd_rt |