Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

L'Huillier Concepts Motorsport Parts

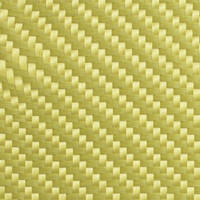

Deciding to make parts for himself at first, followed by customer projects, James was able to gain a lot of composite experience across a variety of fields. Initially his first project involved remaking the panels for a rare Peugeot 205 T16 Group B rally car. He remade the entire body in Kevlar to prepare the car for rally use.

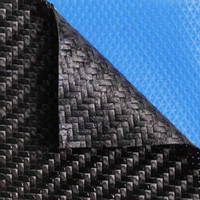

He has expanded his skill base to include the use of carbon pre-pregs and various resins, also he now has his own ovens for curing the parts he makes. Areas he commonly makes parts for is Dakar Rally, Toyota Racing and tailor made parts for individual customers.

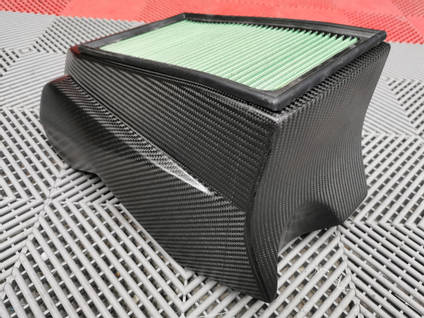

Some of his most notable projects include a 100% pre-preg custom airbox for a Citroen DS3 Rally Cross car and also a custom pre-preg airbox/air filter housing for a, Hayabusa engined, Dallara Single seater race car.

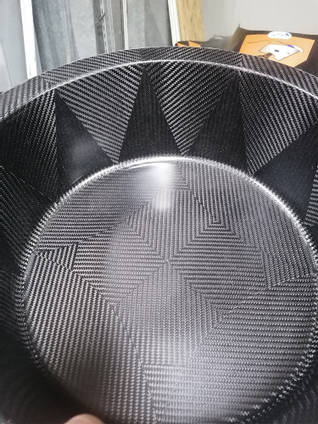

As a different project, a round sink and worktop was also fabricated. The Sink used pre-preg cut up and laid in various shapes and patterns to give an interesting surface finish to the completed sink.

ABOUT L'HUILLIER CONCEPT DEVELOPPEMENT

After a background as a decorated Veteran in the French Navy, across many Continents and Countries, James decided to become self employed and pursued his career working with composites.

His experience gained in the military has equipped him with the skills and determination to carry out complex projects, which has lead to him finishing and developing the various projects he has completed so far in the 14 years since he started making composites.

CONTACT INFORMATION

| www.facebook.com/Lhuillier concept |

| www.facebook.com/Lhuillier concept |