Need any help or advice?+44 (0)1782 454499

Downloads (3)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Dutch Safety DataSheet | ||

| Safety Datasheet (SDS) | ||

| Technical Datasheet (TDS) |

Specification

Product Data

| Colour | Clear | |

|---|---|---|

| Shelf Life | 12 | Months |

| Chemistry / Material | Epoxy | |

| Viscosity | 500 | mPa.s |

| UV Resistance | Very Good | |

| Brand | GlassCast | |

| Maximum Casting Thickness | 10 | mm |

| Machinability | Excellent |

Cured Mechanical Properties

| Max Service Temp | 50 | °C |

|---|---|---|

| Hardness | 83 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 38 - 47 | MPa |

| Flexural Strength | 69 - 78 | MPa |

| Flexural Modulus | 2200 - 2700 | GPa |

| Elongation at Break | 9.0 - 13.0 | % |

| Tg Onset (DMA) | 52 - 58 | °C |

Pot Life and Cure Times

| Pot Life (Typical) | 45 | mins |

|---|---|---|

| Initial Cure Time | 36 | Hrs |

| Full Cure Time | 7 | Days |

Suitable Uses

| Suitable Uses | Flexible Mould | Yes |

|---|

Weight and Dimensions

| Density | 1.10 | g/cm³ |

|---|

Mechanical Properties

| Maximum Strain | 4.5 | % |

|---|---|---|

| Strain at Break | 15 | % |

General Properties

| Gross Weight | 0.58 | kg |

|---|---|---|

| Brand | GlassCast® |

Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 10 Clear Epoxy Casting Resin

- GlassCast®

- EP-G10-05

Hazardous

- 4.5/5 Average rating

GlassCast® 10 is a water-clear, UV resistant epoxy casting resin suitable for castings and deep coatings up to 10mm in thickness. It is recommended for clear jewellery casting, 3D resin art, encapsulation and filling holes and gaps in wood up to 10mm.

Sold as a kit (resin and hardener). Available to buy online in 500g, 1kg, 5kg, 15kg and 30kg kits.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 20 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

GlassCast® 10 is a water-clear, UV resistant epoxy clear casting resin suitable for castings and deep coatings up to 10mm in thickness. It is recommended for clear jewellery resin casting, 3D resin art, encapsulation and filling holes and gaps in wood (up to 10mm) and can be cast in multiple layers to an unlimited depth*. Open surface will require polishing.

Casting Vs Coating

GlassCast 10 is formulated as a casting resin, not a coating resin. This means that whilst it offers the advantage of incredible clarity - even in thick sections - it does not cure with a perfect surface on the open face in the way that our GlassCast 3 coating resin does. However, GlassCast 10 can easily be flatted and polished to acheive a perfectly flat, glossy finish if required.

If your project is more about creating a flat glossy coating - straight from the pour - then our GlassCast 3 coating resin is probably a better option.

Typical Uses

Glass Cast 10 is extremely easy-to-use. It is low odour, easy to mix and measure and does not require vacuum degassing; in fact this amazing resin will drive tiny air bubbles out of the resin during the cure resulting in a perfectly clear, glass-like casting.

All Glass Cast resins have been designed to have exceptional behaviour in contact with wood making them the perfect choice for combining with a wide range of woods including products such as half-wood jewellery (like wood resin rings), paperweights, walking stick handles and furniture pieces.

- Clear or tinted resin jewellery

- Resin & wood jewellery

- Pen blanks

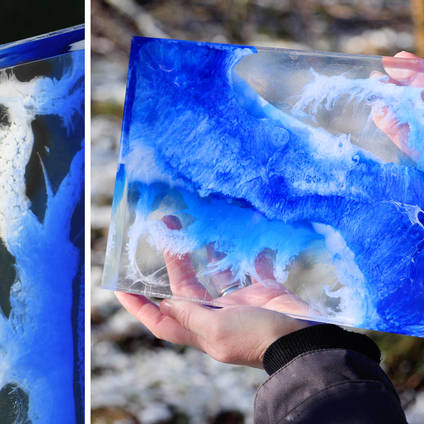

- 3D resin art

- Thick counter-tops (with embedded objects)

- Water effects for models / scenarios

Further Information

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (recommended) | 25°C (maximum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 60 mins | 45 mins | 30 mins |

| Maximum Pour Depth | 10mm | 10mm | 6mm |

| Initial Cure | 48 hrs | 36 hrs | 24 hrs |

Outdoor Use

Despite the very good advanced 'UV' resistant formulation of our Glass Cast resins, we don't suggest using the GlassCast range of resins for permanent, outdoor applications. This is down to epoxy chemistry meaning that eventually, over time, depending on UV exposure, environmental conditions etc, the resins will always eventually yellow in outdoor conditions. How visible this is depends on factors such as the underlying colour and conditions experienced.

We simply don’t have the longevity of testing to be able to guarantee how long it will be before the resin may start to deteriorate in direct sunlight, adverse weather conditions (freezing in winter, high temps in summer), water pooling or sitting on top, etc. We have got customers who have used it for such applications but the advice would be to either put the outdoor projects away between uses or to have a cover to protect it if no other product (yacht varnish, etc.) would suit your project.

Pigments and Tints

To create stunning translucent colours (like stained glass) just add a few drops of our resin tinting pigments. GlassCast can also be enhanced with metal powders, glitters and glow powders to achieve a huge range of decorative effects. It is the perfect clear resin for crafts of all kinds.

Our Glass Cast range of resins are compatible with many pigments and colouring powders on the market today. This includes epoxy compatible pigment pastes, various pigment powders and translucent tinting pigments. If the pigment manufacturer is not sure if the pigment is epoxy compatible then a small test should give you the answer you need. We stock a range of pigments that have all been tested and work great with all of our Glass Cast resins. You can find our range of pigments at the links below.

How to Use

GlassCast 10 should always be mixed, poured and cured at a constant room temperature of around 20°C. Resin and hardener should be mixed 2 parts resin to 1 part hardener by volume (calibrated mixing pots available Here).

For castings, GlassCast 10 can be poured into common mould materials such as silicone**, polyethylene and polypropylene without the need for any release agent. For thick coatings GlassCast 10 can be poured directly onto dry surfaces such as metal, concrete and wood following a light ‘keying’ of the material. For thicker castings up to 50mm, we recommend GlassCast® 50.

*Additional layer should be poured when the previous layer reaches the B-stage of the cure. If the resin has fully cured the surface on the previous layer must be keyed to ensure a strong mechanical bond.

**Unlike most water clear resins, GlassCast can be cast into Condensation/tin cure RTV silicone rubber moulds without any problems.

Download the Technical Datasheet and Safety Datasheet from the 'Downloads' tab for full details on correct and safe measuring, mixing and use of the product.

Shelf Life

Shelf Life is 12 months from date manufacture. GlassCast should be stored in its original container and out of direct sunlight. It is recommended that the storage temperature should be between 15ºC and 25ºC. Ideally, containers should be opened only immediately prior to use. KEEP THE PACKING TIGHTLY SEALED WHEN NOT IN USE. When stored correctly, the resin and hardener will have a shelf-life of 12 months. Although it may be possible to use the resin and hardener after a longer period, a deterioration in the performance of the resin will occur.

GlassCast® 10 is a water-clear, UV resistant epoxy clear casting resin suitable for castings and deep coatings up to 10mm in thickness. It is recommended for clear jewellery resin casting, 3D resin art, encapsulation and filling holes and gaps in wood (up to 10mm) and can be cast in multiple layers to an unlimited depth*. Open surface will require polishing.

Casting Vs Coating

GlassCast 10 is formulated as a casting resin, not a coating resin. This means that whilst it offers the advantage of incredible clarity - even in thick sections - it does not cure with a perfect surface on the open face in the way that our GlassCast 3 coating resin does. However, GlassCast 10 can easily be flatted and polished to acheive a perfectly flat, glossy finish if required.

If your project is more about creating a flat glossy coating - straight from the pour - then our GlassCast 3 coating resin is probably a better option.

Typical Uses

Glass Cast 10 is extremely easy-to-use. It is low odour, easy to mix and measure and does not require vacuum degassing; in fact this amazing resin will drive tiny air bubbles out of the resin during the cure resulting in a perfectly clear, glass-like casting.

All Glass Cast resins have been designed to have exceptional behaviour in contact with wood making them the perfect choice for combining with a wide range of woods including products such as half-wood jewellery (like wood resin rings), paperweights, walking stick handles and furniture pieces.

- Clear or tinted resin jewellery

- Resin & wood jewellery

- Pen blanks

- 3D resin art

- Thick counter-tops (with embedded objects)

- Water effects for models / scenarios

Further Information

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (recommended) | 25°C (maximum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 60 mins | 45 mins | 30 mins |

| Maximum Pour Depth | 10mm | 10mm | 6mm |

| Initial Cure | 48 hrs | 36 hrs | 24 hrs |

Outdoor Use

Despite the very good advanced 'UV' resistant formulation of our Glass Cast resins, we don't suggest using the GlassCast range of resins for permanent, outdoor applications. This is down to epoxy chemistry meaning that eventually, over time, depending on UV exposure, environmental conditions etc, the resins will always eventually yellow in outdoor conditions. How visible this is depends on factors such as the underlying colour and conditions experienced.

We simply don’t have the longevity of testing to be able to guarantee how long it will be before the resin may start to deteriorate in direct sunlight, adverse weather conditions (freezing in winter, high temps in summer), water pooling or sitting on top, etc. We have got customers who have used it for such applications but the advice would be to either put the outdoor projects away between uses or to have a cover to protect it if no other product (yacht varnish, etc.) would suit your project.

Pigments and Tints

To create stunning translucent colours (like stained glass) just add a few drops of our resin tinting pigments. GlassCast can also be enhanced with metal powders, glitters and glow powders to achieve a huge range of decorative effects. It is the perfect clear resin for crafts of all kinds.

Our Glass Cast range of resins are compatible with many pigments and colouring powders on the market today. This includes epoxy compatible pigment pastes, various pigment powders and translucent tinting pigments. If the pigment manufacturer is not sure if the pigment is epoxy compatible then a small test should give you the answer you need. We stock a range of pigments that have all been tested and work great with all of our Glass Cast resins. You can find our range of pigments at the links below.

How to Use

GlassCast 10 should always be mixed, poured and cured at a constant room temperature of around 20°C. Resin and hardener should be mixed 2 parts resin to 1 part hardener by volume (calibrated mixing pots available Here).

For castings, GlassCast 10 can be poured into common mould materials such as silicone**, polyethylene and polypropylene without the need for any release agent. For thick coatings GlassCast 10 can be poured directly onto dry surfaces such as metal, concrete and wood following a light ‘keying’ of the material. For thicker castings up to 50mm, we recommend GlassCast® 50.

*Additional layer should be poured when the previous layer reaches the B-stage of the cure. If the resin has fully cured the surface on the previous layer must be keyed to ensure a strong mechanical bond.

**Unlike most water clear resins, GlassCast can be cast into Condensation/tin cure RTV silicone rubber moulds without any problems.

Download the Technical Datasheet and Safety Datasheet from the 'Downloads' tab for full details on correct and safe measuring, mixing and use of the product.

Shelf Life

Shelf Life is 12 months from date manufacture. GlassCast should be stored in its original container and out of direct sunlight. It is recommended that the storage temperature should be between 15ºC and 25ºC. Ideally, containers should be opened only immediately prior to use. KEEP THE PACKING TIGHTLY SEALED WHEN NOT IN USE. When stored correctly, the resin and hardener will have a shelf-life of 12 months. Although it may be possible to use the resin and hardener after a longer period, a deterioration in the performance of the resin will occur.

Specification

Product Data

| Colour | Clear | |

|---|---|---|

| Shelf Life | 12 | Months |

| Chemistry / Material | Epoxy | |

| Viscosity | 500 | mPa.s |

| UV Resistance | Very Good | |

| Brand | GlassCast | |

| Maximum Casting Thickness | 10 | mm |

| Machinability | Excellent |

Cured Mechanical Properties

| Max Service Temp | 50 | °C |

|---|---|---|

| Hardness | 83 (Hard) | Shore D |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 38 - 47 | MPa |

| Flexural Strength | 69 - 78 | MPa |

| Flexural Modulus | 2200 - 2700 | GPa |

| Elongation at Break | 9.0 - 13.0 | % |

| Tg Onset (DMA) | 52 - 58 | °C |

Pot Life and Cure Times

| Pot Life (Typical) | 45 | mins |

|---|---|---|

| Initial Cure Time | 36 | Hrs |

| Full Cure Time | 7 | Days |

Suitable Uses

| Suitable Uses | Flexible Mould | Yes |

|---|

Weight and Dimensions

| Density | 1.10 | g/cm³ |

|---|

Mechanical Properties

| Maximum Strain | 4.5 | % |

|---|---|---|

| Strain at Break | 15 | % |

General Properties

| Gross Weight | 0.58 | kg |

|---|---|---|

| Brand | GlassCast® |

Yes, you can do an oven post cure of the coasters. The reason a post cure is helpful is that epoxy resins like these have a very long tail end of the cure when cured only room temperature. This means that over several weeks, the properties of the resin - including heat resistance - will develop as the resin cures fully. Typically after 7 days most of the resin is cured, however the post cure process will improve on that further as well as speeding up the process.

To do the post cure, you need access to an oven which has a reasonably accurate temperature control. The actual post cure cycle is to initially cure the resin for 24 hours at room temperature, followed by curing in the oven at 60° for 16 hours. Once allowed to cool to room temperature, the coasters will then be ready for use. Doing this post cure will give a heat distortion temperature of around 55 - 58°C which means you even less likely to get rings or marks from hot cups or plates.

If you are unable to get access to an oven for post curing, the resin does still perform well after allowing the resin a full 7 day cure at room temperature. Following a full 7 day cure, a very subtle ring may still be left by leaving an extremely hot cup to stand on the surface of the resin, this mark is slight and can usually only be seen if the surface reflection is inspected closely. Customers who use this resin for drinks coasters report that the marking is almost un-noticeable in practical applications and continue to use GlassCast commercially for coaster applications.

In its in-mixed state (i.e. a bottle of resin and a bottle of hardener) then both parts should be considered toxic and handled appropriately (wear gloves and eye protection, work in a ventilated area, don't ingest etc.). Once the resin and hardener have been correctly mixed and fully cured then the end result is a stable and inert plastic that is not toxic. Being non-toxic is different from being FDA approved or 'food safe' however so we don't suggest making cups or plates but as a general description the cured end result is just a stable plastic material.

We would not recommend this resin for casting over projects such as a penny floor. However, we do have the perfect resin designed just for this application, our GlassCast Clear Epoxy Surface Resin.

Our GlassCast is a remarkable clear epoxy resin developed specifically to provide a beautiful, hard wearing, clear gloss surface for tabletops, bartops, decorative floor effects, furniture and creative projects, including projects such as your coin floor. The finish is very clear and has a high level of UV resistance so should look amazing for years to come.

All of our epoxy resins (including the GlassCast range) are safe to use on and will NOT dissolve or eat into styrofoam or any other polystyrene based foam.

Although fully cured epoxies are inert and unlikely to pose a hazard, none of the GlassCast range of resins are officially certified food safe and as such we cannot recommend their use where you would need the product to be certified food safe.

As long as the paint has fully dried then we would expect there to be no problems with the GlassCast range being applied over the water based paint.

The GlassCast range of products are not designed for permanent outdoor use. Although the GlassCast resins have a very high level of UV resistance, the very high levels of UV exposure and the variety of inclement weather and environmental conditions experienced mean that the resin would degrade if permanently used outdoors.

Certainly, we can sell the resin and hardener separately if you need extra of either one one its own. Although not listed on the website we can do this over the phone or you can email us and we can send you an invoice with the correct amounts on it. The hardener for each of the GlassCast products is unique for that product. Using hardeners from other resin systems will cause serious curing issues or it may not cure at all.

Any mild soap and detergents will be fine for cleaning GlassCast Resin. Try to avoid strong acids or bases or neat cleaning products as it is possible they may dull the surface finish.

Hi Nicole, this would slightly depend on how you'll be making up that total depth. Generally speaking, flower preservation castings are done in at least 2 pours often more. At the very least, the first pour is usually used to provide a clear 'shelf' on which to position the flow so that it appears suspended in the final casting.

If you're doing multiple pours on a casting that will be a total of 7cm thick then it will probably mean that no single pour exceeds the 50mm maximum (per pour) for GlassCast 50 (when pouring into a mould) and so you could use GlassCast 50.

If you wanted to do the whole depth (50mm or more) in a single pour however then you would need to choose the GlassCast 50 PLUS. 50 PLUS allows you to cast up to 100mm (into a mould) in a single pour with a lower risk of the resin over-heating during its cure. This makes it great for big/deep castings and would make it a good choice for 50-70mm flower preservations but the trade off is that it does mean that it takes a lot longer to cure; around 7 days compared to 48hrs for GlassCast 50.

The resin would not dissolve a 3D printed mould (made using any of the standard polymers) however you will need to think about how you go about sealing the surface of the mould. 3D printed objects tend to have quite a coarse surface that is difficult to release from, even with the use of a release agent. Depending on how coarse this surface is you might need to specifically seal or surface (coat) the mould with something. If you do go for release agent only then I would suggest using something like our Easy-Lease chemical release agent but apply a great number of layers (maybe 10+) in order to achieve a proper build-up of the solids in the release agent. These should help to fill the coarseness of the surface. You would need to test this though because it really depends on the resolution of your printer, the polymer used and what finishing you've done on it.

Unfortunately the GlassCast range of resins are NOT designed to be thinned in use.

Yes you can. Once the 10/150 surface has cured to a B stage, you can use GlassCast 3 directly on top. Alternatively if the surface has fully cured, key it with 120 grit sand paper and thoroughly clean prior to pouring the resin. To get a nice smooth finish, you would need approximately 2kg per square meter to ensure there is enough resin for it to self level evenly. GlassCast 3 used in this way will provide a high gloss and smooth finish that does not need further polishing.

No, we wouldn’t suggest Epoxy Resins for lining a fuel tank. In general, epoxies have good resistance to petrol and many of the chemicals and additives found within pump fuel however the ethanol in fuel is known to cause problems over time and so specialist tank lining resins (often novalac vinylester based) should be used instead. One such product is GTS 1750 which is sold by Caswell Europe.

No, this epoxy in common with other epoxies does not attack expanded polystyrene

We have not specifically saught FDA (or similar) approval for this resin system so if you were to make these plates commercially then you would either need to make a plate using this resin system and then have it tested and approved safe for food use or use a different resin system that has specifically been approved for food use. Mixed and cured fully and properly the resulting plastic should be stable and non-toxic but testing would be required to prove this. Regarding being dishwasher safe; a dishwasher is a very harsh environment (abrasive, high temperatures, caustic) and so I think it would be quite hard on any resin system. By all means conduct your own tests but I would strongly recommend that a carbon fibre plate was not marketed as 'dishwasher safe'.

Although generally cured epoxies are non-hazardous, none of the products we have are certified food safe and thus we cannot recommend their use with food products.

We recommend Acetone. The brushes must be cleaned before the resin has cured. If you can’t get hold of acetone it’s also possible to use methylated spirits or neat alcohol.

In really simple terms you can think of 1kg of the Epoxy Resin as being 1L. If you want to be really exact (for example if you want to mix the resin and the hardener by volume and not by weight (which we don't recommend because it's unnecessarily complicated) then the relative density of the resin and the hardener, and the mixed product, can be found on the technical datasheet.

We can send any quantity of resin to Portugal. We would use a TNT Road service. To find the shipping cost for any item, simply add it to your basket and then click the 'Estimate Shipping' button on the basket page. The price will then be shown once you chose your shipping country (Portugal).

Unlike other resin systems such as polyester or vinylester, it's very important to get the mix ratios accurate with epoxies. If you get the mix ratio wrong by a small amount (let's say a couple of grams on a small mix) then the resin will still cure but the mechanical properties won't be quite as good as they would have been if the mix ratio had been exactly right. However, if you were to be out by anything more than a few grams then you might find that the resin would not be properly hard when cured and/or may have a tackiness to the finish. This would result in a much weaker repair and needs to be avoided by careful measurements.

Above the HDT of a resin system it will soften slightly and its mechanical properties will start to fall away however a thermosetting plastic (like epoxy) is NOT a thermoformable plastic so it will not start to flow again such that you could melt it out of your part. It's more likely to become slightly soft and then possible more brittle again before eventually starting to burn if you too the temperature high enough. It sounds to me like you need a thermoformable plastic (aka a thermoplastic) with a relatively low melting point. I'd suggest something like PCL.

An elevated temperature post-cure is not required for parts made with epoxy resin however, post curing parts will improve the mechanical properties of the resin (and therefore the part) and so if you have the means to do it then it's certainly recommended. One major advantage to post-curing epoxy is that you will raise the HDT (heat distortion temperature) of the part meaning that it's less likely to soften or distort in higher temperatures. This can be particularly important for parts like a vehicle panel (i.e. hood/bonnet) which could get very hot in the sun. Without a post-cure there is a good chance that the part would effectively post-cure itself 'in situe' when it's in direct sunlight which can cause the resin to soften, sink and then re-harden. When this happens to a fitted part it's likely to distort the surface finish. A part that had been post-cured prior to installation would not have this problem.

Epoxy resins have very little odour and so it's quite viable to use them indoors (i.e. in your house) without upsetting anyone. The resin is almost completely odourless and the hardener has an amonia smell which doesn't really carry or linger.

In this respect epoxies are very different to polyester and vinylester resin which has a very strong smell and cannot realistically be used indoors. As always, you should still follow safety precautions and ensure adequate ventilation of your work area.

Uncured resins are classed as dangerous goods and would need to be disposed of correctly. For domestic users, usually your local council recycling centre will have a disposal service for such chemicals or containers.

Because cured resins are inert and safe for disposal it's often easiest to mix un-needed or out-of-date resin and hardener together to cure them. Once cured they can be disposed of with general waste.

Epoxy is sensitive to low temperatures so we would not attempt to try and cure the resin at very low temperatures such as below 15 °:C. At those temperatures, the cure time will be lengthened considerably.

One of the most significant problems caused by low temperatures (much below 20°C) is that the resin will be considerably thicker which affects its ability to self-degas after pouring.

Also, curing epoxies are hydroscopic so the low temperature environment may well leave the resin vulnerable to absorbing moisture, especially if the environment is relatively damp or high in humidity as can be found in some outdoor workshops or home garages.

As a result, for best results we always recommend working in an environment that is 20°C or above.

The B stage of the cure is when the resin has cured enough to be firm but still tacky. When touching with a gloved finger, the resin should feel tacky but not leave any residue on the glove.

Depending on the pebble size, then yest GlassCast 10 should work fine. If the pebbles are large and it is likely you will need a pour much greater than 10mm thick, then we would recommend using our GlassCast 50 which can be used for thicker pours.

Hi Andrew, that's a good question. We tend to think of pen blank dimensions being a little less than the 20-25mm you're describing and in many cases there is a 'core' down the middle of the blank mould which means the resin doesn't occupy the full volume of the enclosure, which increases the section that can be cast without the resin overheating. When casting blanks that are more like 15mm, or a little larger if they have a hollow core, then in almost all circumstances you'd be fine using the GlassCast 10 and the higher reactivity would mean the blanks would cure more quickly (1 day compared to 2 or more) which for a lot of our customers is a significant advantage. However, if speed of cure is not really important, or you're casting blanks over 15mm or without a core then GlassCast 50 would be a better option. The two resins are identical, it's only the speed of the hardener that's different. In your case (20-25mm) it certainly sounds like GlassCast 50 would be the better option.

Both parts of the material (the resin and the hardener) are in bottles which are much bigger than they really need to be but that is because we have to use special UN approved bottles and packaging for resins and other Dangerous Goods and there are only so many sizes of these available. The weight on the bottle applies to the weight of the contents and the combined weight of the resin (Part A) and the hardener (Part B) equal the total kit weight.

GlassCast 10 is rated up to 50°C. This makes it unsuitable for use with very hot cups and plates. As such we would only recommend their use for decorative or colder temperature drink/plate use to prevent the part being damaged. Hot plates or cups may well leave a ring on the surface.

Yes the cured GlassCast 10 can be turned in a wood lathe and machined with woodworking tools in general. Allow a minimum of 48 hours to fully harden before machining begins.

Yes, steel brackets or other 'hard points' could be encapsulated into the lower portion of the pour either as is, or recessed into the wood for a flush finish. You would need to ensure the hidden surfaces are fully keyed on the plate to help with adhesion of the metal to the resin. Finally it would be necessary to drill and clean the threads with a tap to ensure the plate is effective.

The GlassCast 10 product you've identified would work well for this application however you'll need to add something to the resin to match the colour of the granite. If the granite is basically a solid colour (like black) then adding a solid epoxy colour pigment will be your best option. If the granite is more multi-coloured or speckled then of course this will make things more complicated, especially speckles which would be almost impossible to reproduce in a 3 dimensional repair and have a perfectly matching result. In this situation, it's sometimes actually better to cast a clear repair and let the granite behind show through the clear repair.

Because the damage is a chipped front edge, as well as the GlassCast 10 resin and pigment you will also need something to contain the resin whilst it cures. For this you could either use some of our Flash/Release Tape or cut a strip of polypropylene plastic and clamp/stick it in place whilst the resin cures. Finally, you might have a little flatting and polishing to blend the repair in perfectly.

Yes you can apply varnishes over the top of GlassCast 10. We would recommend giving the surface a light key and thorough clean to aid best adhesion.

Although it may work reasonably well, this is not the ideal resin for that purpose. For coating fishing lures, we would recommend our XCR Epoxy Coating Resin. This is specifically designed to provide a high gloss coating.

... fill in cracks, knots and missing chunks in timber that is going to be turned on a lathe?

The choice of resin is down to the size of the cracks and chunks. For voids under around 10mm in size, then our GlassCast 10 is the product to use. For larger knots and voids greater than 10mm then we would recommend our GlassCast 50

The resin will reach its full cure after approximately 7 days.

It would be possible to use the GlassCast 10 for a river table but the normal choice would be our GlassCast 50 Clear Epoxy Casting Resin product which was basically developed specifically for river table applications.

The reason why you would choose GlassCast 50 over GlassCast 10 for a river table is the thickness and size of the section. GlassCast 50 is designed for larger castings (up to 50mm thick in the right circumstances) whereas GlassCast 10 should not be cast in thicknesses more than 10mm, otherwise there is a danger that the resin could overheat during curing. If you check out the GlassCast 50 product page you'll find a whole host of information on using that product for a live edge river table.

We always recommend sealing a wood surface before coating with any of the GlassCast resins. This is because the resin can soak in displacing air and causing bubbles in the resin. Brushing a thin sealing coat of GlassCast over the wood and allowing it to fully cure will prevent this occurring. You would then just need to re-key the surface with sandpaper prior to your main GlassCast pour. Ordinarily you would use the same GlassCast product to seal with as the main pour.

Providing that the wetroom floor was fitted and used in the conventional way; i.e. it was occasionally wet and other times allowed to dry then - other than considerations around slipperiness - it should be OK to use GlassCast for this application.

GlassCast 3 can be poured over both GlassCast 10 and GlassCast 50 to give a smooth finish without the need for further sanding and polishing. The epoxy surface will need to be keyed with a 240 grit abrasive paper and thoroughly cleaned prior to pouring the GlassCast 3.

ASK YOUR OWN QUESTION

Customer Product Reviews for GlassCast 10 Clear Epoxy Casting Resin

My favourite resin to work with very clear. Bubbles go quickly with little effort. Minimal smell. Good working time. I've tried other cheaper resins but always come back to glasscast.

Very pleased so far on first ever use of resin. Hardly any bubbles and removed those that appeared with a heat gun. Will be purchasing again once you get some stock in.

Best resin I have found so far. Very few bubbles and crystal clear when cured.

Glasscast is by far the best resin I've ever used. It's head and shoulders above the standard art/craft resins. I've used both the 10 and the 3 versions and they are both excellent, I tend to give a topcoat of 3 after the 10 has cured to give that amazing glass finish.

I have experimented with lots of different brands over the last two years. I can honestly say as a resin artist no one on the market in my opinion can beat GlassCast. The clarity of GlassCast is the best I’ve seen!

Easy to use, secret is to read all instructions in full and measure out quantity accurately and take time.

Works well, will order again + very helpful service.

GlassCast 10 is easy to use. It mixes well with virtually no air bubbles and cures to a smooth, clear finish.

A little goes a long way - Great product. Easy to use. Lovely results.

Fantastic Product

I started using Glass Cart resin after I found the other resins I had tried to lack hardness. I bought Glass Cast Resin following a recommendation from another resin Artist and I have been blown away at how strong the resin is once cured. I have tried the Glass Cast Resin 3 and 10 and I am a huge fan of them both. I would definitely recommend the product.

I now use Glasscast for all my resin projects. After trying a few different resins, on the quest for the best one, Glasscast is way above any others. I have used Glasscast 3 for my thinner pours like geodes, and top coating. The shine and glossiness is second to none. I also use Glasscast 10 for my castings of smaller pieces. I won't be using any other brand now that I have found "the one".

I’m a floral resin artist and would give glasscast 5/5, and more if possible. I use glasscast 10 and glasscast 50 and it’s by far the clearest resin I have found. Very easy to work with and I wouldn’t hesitate in recommending this brand to other floral artists.

Amazing resin and really great to make all kind of projects. I use mainly GlassCast Resin 10 to make custom knife handles, pens, jewelry and all kind of crafts. The online shop is very intuitive and easy to use. Highly recommended!

I took the plunge and changed resin company. GlassCast grabbed my attention from the start. Made it really easy to understand which type of resin to use for what job. and I've never looked back! Clear, easy to work with. Minimal bubbles and cures with perfection.

Ordered GlassCast 10 for the first time on Monday, arrived next day and I had a play straight away. Fantastic product, best resin I've tried so far. My makes are clear, really smooth and lovely to touch and took less than 24 hours to set. Would highly recommend!

Ace resin love GlassCast 10 I’ve used it for all my casting projects.

Love the GlassCast range for my projects. Highly recommend.

I purchase the GlassCast10 product for my floral resin pieces and I cannot praise it enough. So easy to work with, little to no smell and clear as glass when cured. Makes my pieces look beautiful! I would also like to say thank you for all the advice that I have been given - it has proved invaluable and helped me along my resin journey! Couldn’t recommend enough.

Fast delivery, does the job well.

Product is excellent

Very pleased with this resin . After messaging GlassCast and being advised which resin was best for my project . Excellent and will definitely use again

Quality, amazing product. Love working with it. And it is clear if poured and cured in adequate temperature.

Hi, this is fantastic, what I found was that after mixing there where a lot less bubbles than the other products purchased. I would buy this again.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.