Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

CUSTOMER GALLERY

Group C Inspired Race Car Build

Mark's project is a 1980s Group C car replica capable of 250 MPH with 750 BHP, 600 lb/ft of torque, less than 1000Kgs weight.

Mark started the design around 15 years ago and now he has the time, space and money the project has come to fruition.

To learn all about the project from it's conception you can follow Mark's story by following the links below.

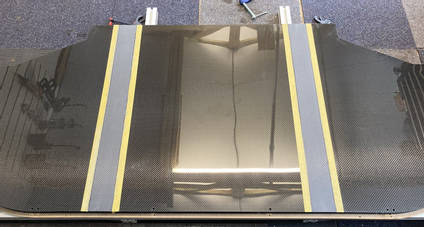

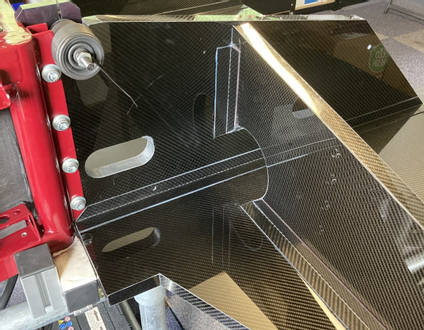

To produce the carbon fibre crush box structure for the front of the 250 mph racing car Mark used carbon fibre flat sheet, structural foam and space rated adhesives to manufacture a large structure incorporating 3D printed caps and internal structures to mount to the chassis and take radiators and brake cooling ducts.

Mark's main goal is to build a road-legal car that looks, goes and sounds like a Group C car -we look forward to seeing the project completed.

ABOUT GRP C MOTORSPORTS

Mark is a mechanical engineer with 20+ years of professional experience. Straight from school Mark worked as a toolmaker, earning his stripes on grinders, lathes, mills, CNC machines and more.

After getting a taste for working with metal, Mark decided to make it official and began studying for his degree in Automotive Engineering.

With a love of fast cars and loud races, Mark decided to design his own racing car!

The design is around the Group C rulebook and you can learn all about the project on Marks website via the link on the right.

CONTACT INFORMATION

| Website | https://grpcmotorsport.com/ |

|---|

| @grp_cmotorsports |

| Twitter - @GrpC_Motorsport |

| Website | https://grpcmotorsport.com/ |

|---|

| @grp_cmotorsports |

| Twitter - @GrpC_Motorsport |