Need any help or advice?+44 (0)1782 454499

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

VACUUM BAGGING CONSUMABLES

TOOLS & EQUIPMENT

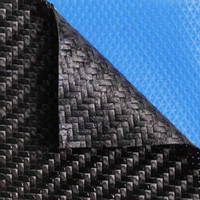

REINFORCEMENTS

VIDEO TUTORIAL

Laminating and Bagging a Carbon Fibre Tube Using a Split Mould

In this video tutorial we take a detailed look at how to laminate and then vacuum bag tubular composite components using a split-mould process with an internal vacuum bag.

This process can be used to produce non-straight tube forms such as carbon fibre handlebars, kayak paddles and induction tubes. It can also be used for very complex tubular structures such as carbon fibre bike frames and suspension wishbones. In fact, this video is intended to provide a more detailed look at the laminating methodology and vacuum bagging principles used in our video tutorial on how to make a carbon fibre bike frame.

In situations where only a straight tube form is required, the roll-wrapped tube manufacturing method would often be more appropriate, or in commercial manufacture processes such as pultrusion or pulwinding, can also be used. However, none of these processes can be used for curved/bent tubes or complex tubular structures.

BACKGROUND

What about internal bladders?

This method is an alternative to the internal pressurised bladder method often used in bike frame production which requires much more substantial moulds, usually machined from solid billets of aluminium, which need to resist the deformation caused by the unbalanced pressure of the internal bladder.

By exerting pressure equally on the inside and outside of the mould, this internal vacuum bagging method causes little or no distortion of the mould, allowing much lighter – and lower cost – moulds to be used.

What about autoclave curing?

Although in this tutorial we demonstrate the process using only vacuum pressure with the component then cured in a conventional oven (known as out-of-autoclave prepreg), the exact same process can be - and is - used for high pressure curing of tube and frame structures in an autoclave. For autoclave curing, there would be no need to change any of the materials, layup or vacuum bagging process shown in this tutorial.

In common with the vacuum only out-of-autoclave cure, autoclave curing using this same internal vacuum bag configuration also creates equal pressure on both sides of the mould, allowing these lighter weight composite tools to be used.

Does it have to be prepreg?

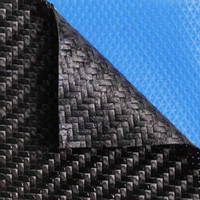

Making complex carbon fibre tube or frame mouldings is almost exclusively done using the prepreg moulding process. The reason for this is mainly due to the practicalities of accurately cutting, handling and positioning the reinforcement within the split mould, manipulating this reinforcement when the mould is closed up and then working around the reinforcement to position the vacuum bagging consumables. All of these processes would be difficult or almost impossible if attempted using a traditional wet-layup method or alternative vacuum moulding processes such as resin infusion of dry fabric.

In this video we use the XPREG XC110 out-of-autoclave carbon fibre prepreg, oven cured using a ramped temperature profile up to 120C; video tutorial on making prepreg carbon fibre parts out-of-autoclave here.

Suitable tool/mould materials

Because this tutorial uses prepreg carbon fibre reinforcement, the component must be cured in an oven at elevated temperature. It is therefore essential that the material the mould is made from has a sufficiently high service temperature. The mould used in this tutorial was made using our XT135 out-of-autoclave carbon fibre tooling prepreg system; video tutorial on making prepreg carbon fibre tools out-of-autoclave here.

Alternatively, the mould could be hand-laminated using a high temperature epoxy tooling system, such as our EG160/EL160/EMP160 products; video tutorial on hand laminating a high temperature epoxy mould here.

TUTORIAL BREAKDOWN

1. Templating and cutting the first ply of prepreg

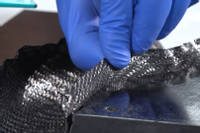

To get an approximate shape to cut the prepreg reinforcement to, masking tape is applied onto the surface of one half of the split-mould. The masking tape is then removed and then positioned onto the prepreg reinforcement. Because the template won't yet be accurate, it is extended by about 1cm in all directions.

The rough-shape prepreg is then laminated into the mould. Once it's fully in place, any overhanging reinforcement is then carefully cut off to leave the reinforcement cut exactly to size, flush with the edge of the split.

The offcuts of carbon fibre are then put back onto the backing paper so that the paper can be cut to create a precise template that allows exactly for how the reinforcement drapes into the mould. This template can be retained for future use.

2. Templating the staggered laps

When laminating reinforcement into a split-mould, it is essential that most of the reinforcement continues over the split-line, avoiding a weak point at this join. Without overlapping any reinforcement, the two halves of the component would simply fall apart from each other!

Layers of reinforcement that continue over the split-line are call the overlaps, or 'laps'. To avoid creating other weak-points in the laminate, these laps themselves are staggered by making them different sizes. In the tutorial, the overlapping pieces of reinforcement are cut to 5mm, 10mm and 15mm wider than the split-line.

To try to maintain a consistent wall-thickness around the tube, the corresponding pieces of reinforcement for the other half of the tube are cut narrower than the split line. However, in order to create some overlap of the overlaps, the reinforcement on this shorter side is in fact cut slightly larger than it would be if the reinforcement was to meet in a perfect butt-join.

3. Adding the 'lapped' plies

The 'oversized' plies are laminated into the opposite side of the split-mould, in sequence.

The first ply to be added has the smallest (5mm) extension, designed to slightly overlap the cut-to-size first ply in the other side of the split-mould. Next the 10mm and 15mm extension plies are added.

Returning to the first side of the split-mould (which already has the cut-to-size ply in it) the two shorter plies are added to this half, again in sequence getting progressively shorter to match the progressively longer overlaps on the extension side.

4. Adding the tubular bagging film

The vacuum bagging configuration in this tutorial is an internal tubular vacuum bag. This involves running length of tubular bag through the middle tube split mould and then linking this tube up to an external 'envelope' bag on the outside of the mould.

The type of tubular bagging film we use is our VB155 self-releasing, gusseted tubular bagging film in a 100mm width.

With the tubular bagging film inside, the two halves of the mould are carefully brought together, paying attention to ensure that the 'laps' are correctly positioned and do not get folded or trapped as the mould is closed.

5. Completing the vacuum bag

To begin with, the outside of the split mould is wrapped in BR180 breather cloth to provide an airflow path and prevent any accidental puncturing of the vacuum bag by any sharp details on the mould.

Next, the entire mould will be surrounded by a large 'envelope' bag of VB160 vacuum bagging film. The principle is that the tubular vacuum bag will create a 'tunnel' through the middle of the envelope bag. When the vacuum is pulled it will be pulled from inside the envelope bag, sucking the bag down onto the outside of the mould and the tubular bag onto the inside of the tube.

To create this 'tunnel' through the bag, the outside of the tubular bag is sealed to the inside of the envelope bag using some vacuum bagging sealant tape.

A full vacuum is then pulled on the vacuum bag using our EC.4 composites vacuum pump. Careful checking is undertaken to ensure that the vacuum bag is perfectly sealed with no leaks.

6. Oven cure the prepreg

The vacuum bagged part is then transferred to an oven to cure. Because we're using the XPREG XC110 out-of-autoclave prepreg to make this component then a specific cure cycle needs to be followed in order to get the best results. See the XC110 processing guide for full details on recommended cure cycles and processing for XPREG XC110.

DISCUSSION (19)

Please share any questions or comments you may have about this video tutorial.

The environmental impact of composites is a little more nuanced than simply looking at some of the plastic consumables used in the manufacturing process. Generally speaking, advanced composites is now looked to as being highly significant for the production of lighter, more efficient technology, especially in transport. If you need to use a metre or two of bagging film to save a kilogram off the weight of an aircraft door component then the reduction in fuel needed over the lifetime of the component would dwarf the environmental impact of the films and manufacturing process used to make the component. Advanced composites is already saving thousands of tonnes of CO2 every year in passenger aircraft and other mass transit applications. Disposed of in a responsible way, plastic film causes no environment harm but the lightweight component helps to reduce climate change throughout its life.

LEAVE A COMMENT OR QUESTION

PRODUCTS USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

VACUUM BAGGING CONSUMABLES

TOOLS & EQUIPMENT

REINFORCEMENTS

DISCUSSION (19)

Please share any questions or comments you may have about this video tutorial.

The environmental impact of composites is a little more nuanced than simply looking at some of the plastic consumables used in the manufacturing process. Generally speaking, advanced composites is now looked to as being highly significant for the production of lighter, more efficient technology, especially in transport. If you need to use a metre or two of bagging film to save a kilogram off the weight of an aircraft door component then the reduction in fuel needed over the lifetime of the component would dwarf the environmental impact of the films and manufacturing process used to make the component. Advanced composites is already saving thousands of tonnes of CO2 every year in passenger aircraft and other mass transit applications. Disposed of in a responsible way, plastic film causes no environment harm but the lightweight component helps to reduce climate change throughout its life.

LEAVE A COMMENT OR QUESTION

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.