Need any help or advice?+44 (0)1782 454499

Specification

Mechanical Properties

| Max Service Temp | 130 | °C |

|---|

Product Data

| Freezer-life (at -18°C) | 12 | Months |

|---|---|---|

| Out-life (at 20°C) | 30 | Days |

General Properties

| Gross Weight | 5 | kg |

|---|

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Prepreg Carbon Fibre Starter Kit

- SK-PP-CF-REG

- No reviews

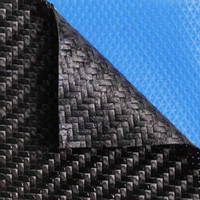

This complete starter kit has been put together as a convenient means for individuals and independent manufacturers to get started with the prepreg composites manufacturing process. The kit includes all vacuum bagging consumables, fittings and accessories, along with starter quantities of the XPREG® XC110 out-of-autoclave carbon fibre prepregs.

A video tutorial is provided below and a detailed processing guide is available from the downloads section.

Available to buy online in Regular (1m x 1.25m) or Professional (5m x 1.25m) kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:5 in stock available for immediate shipping

Optional items

PRODUCT OPTIONSWe won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Brand new updated XPREG® version of our Prepreg Starter Kit.

This comprehensive starter kit has now been updated to include the very latest XPREG® XC110 out-of-autoclave prepreg carbon fibre. Also included in the kit is a complete range of vacuum bagging consumables and connectors to ensure a problem-free and successful start into out-of-autoclave prepreg carbon fibre.

Available in both a regular starter kit size aimed at individuals and also a full 'professional' package for small-to-medium sized businesses wanting to move into cutting-edge prepreg carbon fibre manufacture. See the specification tab for a full list of the components and quantities included in each kit.

Further Information

Compatible Moulds

To get the best results from the XPREG® XC110 prepreg system, you need to have moulds that are suitable for use at 120°C. Composite moulds made using high temperature epoxy resin/gelcoat or epoxy-prepreg are recommended. Fully mould materials include:

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

The following mould materials are fully compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

Although it is possible to use vinylester tools (such as Uni-Mould) they are not recommended due to the increased possibility of surface imperfections (pin holes) which can occur when XPREG® XC110 is cured in the presence of vinylester.

See XC110 Technical Data Sheet and XC110 Processing Guide for full details on mould compatibility.

Curing Oven

To cure the XC110 prepreg carbon fibre included in the kit you will require an oven capable of accurately holding the set temperature, up to 120°C. Programmable ramp rates and set points are advantageous but not essential. You will need to maintain an active vacuum connection inside the oven and so a vacuum port (or hole) through the oven wall is required.

About Prepreg Carbon Fibre

Prepreg carbon fibre components are widely regarded as the pinnacle of advanced composites; their incredible performance and stunning appearance making them the most sought-after performance parts on the market. Prepreg carbon fibre is used to make the chassis and body panels of Formula 1 cars and the wings of the latest 'Dreamliner' passenger jets.

Traditionally, working with prepreg carbon fibre has required always required an autoclave, a very expensive piece of machinery used to cure the prepreg under high pressure and temperature. With this starter kit however, Easy Composites has put together a complete package of materials specially developed to mean that anyone can make stunning prepreg carbon fibre parts with only this kit and an oven (see notes below).

Worldwide Use

The EC.4 Compact Composites Vacuum pump optionally included with the kit can be only used on 240V systems and is available with a choice of power leads for compatibility.

Kit Contents

The kit is available in two sizes; 'Regular' and 'Professional'. There is no difference in the materials used in the two kits and both kits will produce parts of exactly the same professional standard. The only difference is the quantity of the materials included. Both kits are available with or without a Composites Vacuum Pump.

| Regular Kit | Professional Kit | |

|---|---|---|

| XPREG XC110 Prepreg Carbon 3K, 210g, 2/2 Twill | 1m x 1250mm | 5m x 1250mm |

| XPREG XC110 Prepreg Carbon Fibre 6K, 416g, 2/2 Twill | 1m x 1250mm | 5m x 1250mm |

| Unperforated Release Film | 2m x 1.52m | 2 x 5m x 1.52m |

| Vacuum Bagging Film LFT | 5m x 1.52m | 20m x 1.52m |

| Breather Cloth | 2m x 1.52m | 10m x 1.52m |

| Vacuum Bagging Gum Tape | 2x 15m Rolls | 5x 15m Rolls> |

| Through Bag Connector | 1 Unit | 1 Unit |

| 1/4 Turn Valve | 1 | 1 |

| 8mm ID Hosetail Barb Connector | 1 | 1 |

| 8mm ID Silicone Hose | 2m | 5m |

| Nitrile Gloves | 10 pairs | Box of 100 |

| EC4 Compact Composites Vacuum Pump (optional) | 1 | 1 |

Please choose the right kit size for your needs and whether you require a vacuum pump using the drop-down list at the top of the page.

Brand new updated XPREG® version of our Prepreg Starter Kit.

This comprehensive starter kit has now been updated to include the very latest XPREG® XC110 out-of-autoclave prepreg carbon fibre. Also included in the kit is a complete range of vacuum bagging consumables and connectors to ensure a problem-free and successful start into out-of-autoclave prepreg carbon fibre.

Available in both a regular starter kit size aimed at individuals and also a full 'professional' package for small-to-medium sized businesses wanting to move into cutting-edge prepreg carbon fibre manufacture. See the specification tab for a full list of the components and quantities included in each kit.

Further Information

Compatible Moulds

To get the best results from the XPREG® XC110 prepreg system, you need to have moulds that are suitable for use at 120°C. Composite moulds made using high temperature epoxy resin/gelcoat or epoxy-prepreg are recommended. Fully mould materials include:

Suitable Moulds/Tooling

Moulds/tools should be epoxy-based composite moulds, epoxy tooling board or metal. In all cases, moulds must be temperature stable to a minimum of 85°C but ideally to 120°C.

The following mould materials are fully compatible:

- High temp epoxy hand-layup moulds (e.g. EG160 / EMP160)

- Carbon or glass fibre prepreg moulds (e.g. XPREG® XT135)

- Epoxy tooling board (e.g. EB700 Epoxy Tooling Board with S120 Board Sealer)

- Aluminium / stainless steel moulds

- Toughened glass (for flat sheet/panels)

Although it is possible to use vinylester tools (such as Uni-Mould) they are not recommended due to the increased possibility of surface imperfections (pin holes) which can occur when XPREG® XC110 is cured in the presence of vinylester.

See XC110 Technical Data Sheet and XC110 Processing Guide for full details on mould compatibility.

Curing Oven

To cure the XC110 prepreg carbon fibre included in the kit you will require an oven capable of accurately holding the set temperature, up to 120°C. Programmable ramp rates and set points are advantageous but not essential. You will need to maintain an active vacuum connection inside the oven and so a vacuum port (or hole) through the oven wall is required.

About Prepreg Carbon Fibre

Prepreg carbon fibre components are widely regarded as the pinnacle of advanced composites; their incredible performance and stunning appearance making them the most sought-after performance parts on the market. Prepreg carbon fibre is used to make the chassis and body panels of Formula 1 cars and the wings of the latest 'Dreamliner' passenger jets.

Traditionally, working with prepreg carbon fibre has required always required an autoclave, a very expensive piece of machinery used to cure the prepreg under high pressure and temperature. With this starter kit however, Easy Composites has put together a complete package of materials specially developed to mean that anyone can make stunning prepreg carbon fibre parts with only this kit and an oven (see notes below).

Worldwide Use

The EC.4 Compact Composites Vacuum pump optionally included with the kit can be only used on 240V systems and is available with a choice of power leads for compatibility.

Kit Contents

The kit is available in two sizes; 'Regular' and 'Professional'. There is no difference in the materials used in the two kits and both kits will produce parts of exactly the same professional standard. The only difference is the quantity of the materials included. Both kits are available with or without a Composites Vacuum Pump.

| Regular Kit | Professional Kit | |

|---|---|---|

| XPREG XC110 Prepreg Carbon 3K, 210g, 2/2 Twill | 1m x 1250mm | 5m x 1250mm |

| XPREG XC110 Prepreg Carbon Fibre 6K, 416g, 2/2 Twill | 1m x 1250mm | 5m x 1250mm |

| Unperforated Release Film | 2m x 1.52m | 2 x 5m x 1.52m |

| Vacuum Bagging Film LFT | 5m x 1.52m | 20m x 1.52m |

| Breather Cloth | 2m x 1.52m | 10m x 1.52m |

| Vacuum Bagging Gum Tape | 2x 15m Rolls | 5x 15m Rolls> |

| Through Bag Connector | 1 Unit | 1 Unit |

| 1/4 Turn Valve | 1 | 1 |

| 8mm ID Hosetail Barb Connector | 1 | 1 |

| 8mm ID Silicone Hose | 2m | 5m |

| Nitrile Gloves | 10 pairs | Box of 100 |

| EC4 Compact Composites Vacuum Pump (optional) | 1 | 1 |

Please choose the right kit size for your needs and whether you require a vacuum pump using the drop-down list at the top of the page.

Specification

Mechanical Properties

| Max Service Temp | 130 | °C |

|---|

Product Data

| Freezer-life (at -18°C) | 12 | Months |

|---|---|---|

| Out-life (at 20°C) | 30 | Days |

General Properties

| Gross Weight | 5 | kg |

|---|

We recommend keeping pre-preg sealed in its bag in a freezer at -18 °C or colder. Providing it will fit in, most domestic or commercial freezers are perfectly suitable for storing prepregs.

Yes, for a successful cosmetic finish, you will need to maintain constant vacuum throughout the cure process.

We always recommend an active vacuum connection be maintained to the parts throughout the curing process, as in the case of a very tiny leak, it will sometimes not damage the finished parts. If the bag still felt tight after the drop test but a tiny change in the pump not was detectable when opening the valve then this sort of micro-leak can probably be overcome. If, however, the bag actually feels slack after the drop-test then the leak needs to be found or the whole part re-bagged.

If you intend to cure you part in the oven without an active vacuum connection to it then you MUST have a perfect seal. Any leak in the bag whatsoever, without an active vacuum connection, will guarantee a failed part.

....I'm looking to make a large moulding that won't fit in an oven. Can I still use vacuum bagged prepreg and leave for a longer cure time, or will the material not cure at room temperature? In the latter case should I use a wet layup and if so do I still vacuum? Thanks

Unfortunately, no - you cannot cure this prepreg properly without an elevated temperature. At ambient temperature the prepreg would partially cure but this should be considered more of a deterioration of the prepreg, not a proper flow and cure. At room temperature it would take many months for the prepreg to become even partially cured and during this time the resin would never flow in the same was as would in an oven. The end result would not resemble a proper laminate.

If your part is too large for an oven, it might be worth you considering our resin infusion starter kit instead. The resin infusion process will give you parts of comparable quality and performance to those made from prepreg carbon fibre without the requirement to cure the parts in an oven.

ASK YOUR OWN QUESTION

Customer Product Reviews for Prepreg Carbon Fibre Starter Kit

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Shipping 'Prepreg' Products

Prepreg materials are stored in our freezers at -20°C and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

We remind all international customers that it is their responsibility clear goods through their local customs. Any delay caused during customs clearance is outside of our control and as such we cannot refund or replace materials which are found to be damaged or unusable on arrival as a result of delays during customs clearance.

Whilst such delays are very rare, we strongly advise all customers intending to import prepreg materials to contact their local customs agency to seek full clarification of the import procedure and whether delays are likely before placing an order. By placing an order for prepreg materials, you accept these conditions of sale.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.