Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

CUSTOMER GALLERY

Carbon Fibre Mountain Bike

These bikes were made by Anthony to fulfil his passion for MTB and mechanical design and due to a distinct lack of choice of XXL size frames available on the market.

Designed as a single pivot suspension, which has a linear and constant leverage ratio of about 2.4 and a relatively stable pedalling platform. The intent was to create a mid travel full suspension bike which is agile in most situations whether it's long climbs or technical downhills.

These are the bikes for anyone who love spending time on the saddle, climbing long tracks and then enjoy bigger features like obstacles and rock gardens.

The first image shows Anthony's first bike which was finished with clear coated XPREG prepreg carbon fibre and later images show it painted green and reassembled for a completely new look.

The other bike featured is the black carbon with gold chain and yellow branding.

The process for the bikes was as follows; to create the front triangle, Anthony used High temp epoxy gelcoat and epoxy mould putty to build a conventional split mould. A scale 1:1 3D print of the frame, coated with board sealer was used as the pattern. To create the swingarm he used two almost symmetrical 3D printed moulds made of Polycarbonate filament, reinforced with epoxy mould putty and coated with board sealer.

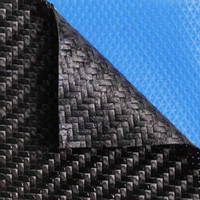

Both parts were laminated using a combination of the XPREG XC110 prepreg carbon fibre twill and XPREG XC130 unidirectional, and cured in a large home made curing oven, with pressure applied using tyre inner tubes.

The two halves of the swingarm were then bonded and the bikes assembled.

Anthony's bikes have been featured in the popular French Cycle magazine Velo Vert!

ABOUT ANTHONY POILLOT

Anthony Poillot was born in France in 1984. He always liked to learn how things were made and decided to follow this path to learn more at an engineering school.

He works as product engineer in the hand tool industry and always had the wish to merge his work with his passion for MTB. In 2016 he decided to start his own composites project. Anthony knew that he wanted to use a basic but efficient suspension design combined with a more complex and organic shape for the frame and swingarm.

Next Anthony booked on to one of our Advanced Composites 3 day Training Courses which was key for him to make progress in the project and really kept pushing to make it happen. He believes that patience, motivation and dedication are key to succeed, along with good materials!

CONTACT INFORMATION

| Website | www.monotrace.jimdofree |

|---|

| @monotrace_cycles |

| www.facebook.com/monotracecycles |

| Velo Vert Issue 315 | www.shop/velovert.com/315 |

|---|

| Velo Vert Issue 324 | www.shop/velovert.com/bikereview |

|---|

| Website | www.monotrace.jimdofree |

|---|

| @monotrace_cycles |

| www.facebook.com/monotracecycles |

| Velo Vert Issue 315 | www.shop/velovert.com/315 |

|---|

| Velo Vert Issue 324 | www.shop/velovert.com/bikereview |

|---|