Need any help or advice?+44 (0)1782 454499

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

PATTERN MAKING MATERIALS

COMPONENT MATERIALS

MOULD MAKING MATERIALS

PRO CASE STUDY

Ultima RS Carbon Fibre Engine Cover

When V8CREATIVE's Nigel Dean approached us regarding a problem he encountered with the look of his Ultima RS Engine Bay, we decided to work with him to create a bespoke engine cover which would lift the look to a level never seen before!

Having followed the Ultima RS build on Nigel's YouTube channel it made perfect sense for Easy Composites to get involved in this part of the project and lend our expertise to this incredible build.

Nigel and Paul spent time collaborating on ideas, followed by the design going back and forth discussing options before settling upon the final design.

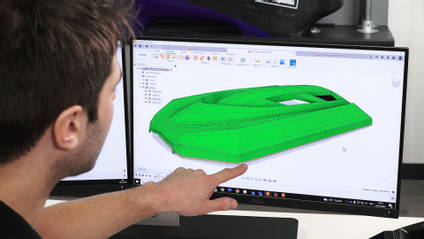

Paul then created a CAD Design which he used to produce the pattern. In turn the pattern was used to create a mould and finally make the part.

For this project the pattern was machined from EB700 Epoxy Tooling Board using the CAD design, then finished with S120 Advanced Board Sealer to seal the surface and give a high quality glossy finish to the pattern. The pattern was then treated with multiple coats of release agent to ensure good release of the mould.

To make the mould, the XT135 Tooling pre-preg was used. The surface layer was used first against the pattern surface followed by a debulk in a vacuum bag to help fibre consolidation. Two layers of the backing plies were then added to give the mould strength. Using release film, breather and a vacuum bag, the mould could then be cured in the OV301 Composites Curing oven. Once the cure cycle was complete, the mould was removed from the pattern and then trimmed and finished ready for use.

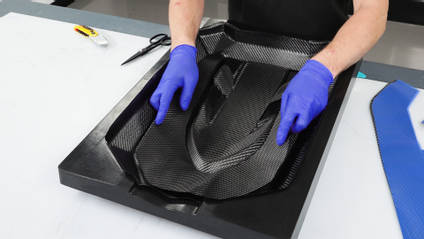

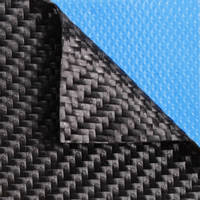

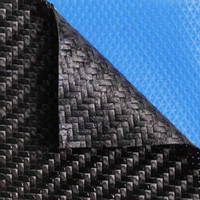

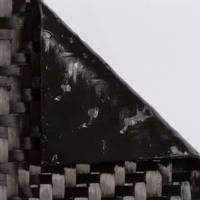

Once the mould was ready, it was treated with multiple coats of release agent and then the Out of Autoclave XC110 pre-preg could be cut and laid into the mould. Due to the precise shapes on the part, cutting templates were drawn up in CAD and then the pre-preg was cut using a CNC router fitted with a drag knife tool. The lighter weight 210g fabric was then laid into the mould and extra attention was paid to ensure perfect alignment and layup as this is the visible side of the part. The second layer used the thicker 416g pre-preg to add strength to the finished part. The mould could then be bagged and cured in a similar fashion to the mould.

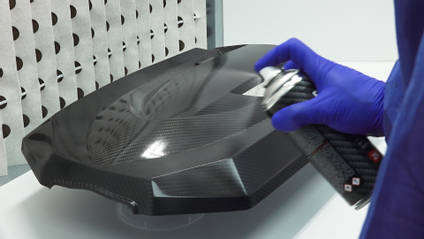

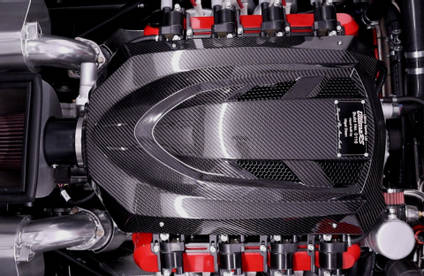

Once the part had been cured, it was then easily removed from the mould. The edges were then trimmed and sanded smooth. To get an even better surface finish, the part was lightly sanded to remove any texture or ripple and was then sprayed with Fantom Clear Gloss Lacquer to give a great smooth and high gloss finish. To neatly finish the holes, Nigel supplied some of the Ultima mesh which was fitted to match the existing grille mesh already on the car. The finished engine cover could then be sent to Nigel, where he bonded on the metal mounting brackets and fitted it to the car.

The finished cover looks stunning on the car and lifts the look of the engine to a new high, befitting of the bespoke and high pedigree nature of the Ultima RS. It successfully hides the skull cap and wires and also compliments the other carbon fibre details already on the car.

To see the Ultima RS project on the V8CREATIVE channel simply click on the YouTube link in the contact information below.

ABOUT V8CREATIVE

‘Creativity is intelligence having fun’. This is how Einstein described the ability to transform ideas into reality.

From a young age, this so-called intelligence has been hard-wired into Nigel. With hours and hours spent nurturing ideas and ultimately turning them into reality.

The journey has been totally immersive and most importantly fun; from Lego, to Mecanno, to Airfix, to Hornby, and then at the age of 17, Nigel's automotive love affair began. Three decades of spannering has yielded an intoxicating back-catalogue of hand-crafted component cars any petrol-head would appreciate.

"I had a problem, that my beautiful RS was not quite perfect. After carrying out a series of enhancements to the 6.2L V8 engine it just doesn't look quite right. The visible wiring and skull cap just didn't suit the pedigree of the RS. I went online and was looking around for some market leading carbon fibre manufacturers and I came across a company called Easy Composites. I had a chat with Paul and he said 'let's work together and I will make a bespoke engine cover that will lift the LS to a level never seen before' - and boy has he delivered!"

Nigel Dean, V8CREATIVE

"Having followed Nigel’s Ultima build on YouTube from the start, I was very happy when he got in touch and that I could get involved with this outstanding build, it may be only a small detail but I’m really pleased with the design that we settled on."

Paul Statham, Technical Director

Easy Composites Ltd

CONTACT INFORMATION

| Website | www.v8creative.com |

|---|---|

| facebook.com/V8creative | |

| @V8creativebuilds | |

| YouTube | @v8creative |

DISCUSSION (0)

Please share any questions or comments you may have about this video tutorial.

LEAVE A COMMENT OR QUESTION

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

MATERIALS & CONSUMABLES

PATTERN MAKING MATERIALS

COMPONENT MATERIALS

MOULD MAKING MATERIALS

ABOUT V8CREATIVE

‘Creativity is intelligence having fun’. This is how Einstein described the ability to transform ideas into reality.

From a young age, this so-called intelligence has been hard-wired into Nigel. With hours and hours spent nurturing ideas and ultimately turning them into reality.

The journey has been totally immersive and most importantly fun; from Lego, to Mecanno, to Airfix, to Hornby, and then at the age of 17, Nigel's automotive love affair began. Three decades of spannering has yielded an intoxicating back-catalogue of hand-crafted component cars any petrol-head would appreciate.

"I had a problem, that my beautiful RS was not quite perfect. After carrying out a series of enhancements to the 6.2L V8 engine it just doesn't look quite right. The visible wiring and skull cap just didn't suit the pedigree of the RS. I went online and was looking around for some market leading carbon fibre manufacturers and I came across a company called Easy Composites. I had a chat with Paul and he said 'let's work together and I will make a bespoke engine cover that will lift the LS to a level never seen before' - and boy has he delivered!"

Nigel Dean, V8CREATIVE

"Having followed Nigel’s Ultima build on YouTube from the start, I was very happy when he got in touch and that I could get involved with this outstanding build, it may be only a small detail but I’m really pleased with the design that we settled on."

Paul Statham, Technical Director

Easy Composites Ltd

CONTACT INFORMATION

| Website | www.v8creative.com |

|---|---|

| facebook.com/V8creative | |

| @V8creativebuilds | |

| YouTube | @v8creative |

DISCUSSION (0)

Please share any questions or comments you may have about this video tutorial.

LEAVE A COMMENT OR QUESTION

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.