Need any help or advice?+44 (0)1782 454499

FILTERS

OTHER CATEGORIES

Vacuum Bagging Equipment & Materials for Resin Infusion

Easy Composites are recognised leaders in resin infusion technology. In this category you will find the vacuum bagging materials and equipment that are most commonly used when undertaking resin infusion of composite parts.

The resin infusion process typically involves laying all the reinforcement - and sometimes core materials - dry into the mould, with no resin. A special set of vacuum bagging consumables and hoses are then positioned before everything is enclosed in a vacuum bag. Once the air has been removed from the laminate, resin is allowed to be drawn into the laminate and infuses through it under vacuum before being clamped off when the infusion is complete.

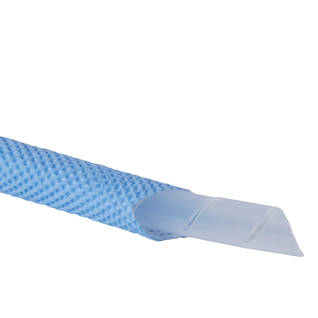

To achieve this a vacuum bagging stack of peel-ply, followed by infusion mesh is positioned onto the dry reinforcement with an infusion spiral used to direct resin flow before everything is enclosed using vacuum bagging film which is sealed to itself or the mould flange using sealant tape. Resin infusion connectors are used to make the resin feed and vacuum connections into the bag, line clamps are used to control resin flow and a catch-pot is used to prevent liquid resin from accidentally reaching the vacuum pump. We have a number of video tutorials demonstrating the resin infusion process in our learning area.

Easy Composites are recognised leaders in resin infusion technology. In this category you will

FILTERS

OTHER CATEGORIES

PRODUCTS (32)

Showing 1-32 of 32

From £35.70

From £1.65

From £1.80

From £18.50

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.